◎ 目录/Catalog

系列 |

类型 |

UL 型号 |

Tg(℃) |

颜色 |

Td(℃) |

T288(min) |

CTE(%) |

备注 |

页码 |

|

FR-4 |

H140A |

135±5 |

黄/自然 |

310 |

2 |

4.3 |

可提供 Tg:140±5℃ 等各种 TG |

3-5 |

CTI600(FR-4) |

H1600A |

135±5 |

黄/自然 |

310 |

1 |

4.5 |

|

8-9 |

无铅/有卤 |

FR-4 |

H140-1 |

135±5 |

黄 |

≥325 |

≥5 |

≤4.0 |

|

10-12 |

H150(LF) |

≥150 |

黄 |

≥325 |

≥5 |

≤3.5 |

|

13-15 |

H1170 |

≥170 |

黄 |

≥340 |

≥15 |

≤3.0 |

|

16-18 |

无卤 |

FR-4 |

H140H |

135±5 |

黄/自然 |

≥325 |

≥5 |

≤4.0 |

可提供 CTI≥600 及苯并恶嗪改性高耐热无卤材料 |

19-21 |

H155H |

150±5 |

黄 |

≥325 |

≥5 |

≤4.0 |

22-24 |

附1. 覆铜板厚度公差表 / CCL thickness and tolerance list

附2:半固化片储存条件/ Prepreg Storage Condition

【H140A】

特性/ Features

Tg:135±5℃ (DSC)

可依需求提供多种Tg值/Different Tg available upon request Tg:140±5℃、Tg≥140℃

UV Blocking与 AOI兼容可提高PCB生产效率

UV Blocking and AOI compatible,so as to increase productivity efficiency

可依需求提供仪表专用的FR-4板材/the meter appropriative FR-4 CCL upon request

可依需求提供不具UV阻挡功能的自然色板材(白料)/No UV Blocking and natural color CCLupon request

应用领域/ Applications

适合于2-6层PCB、计算机及外围设备、通讯设备、办公自动设备等。

Suitable for medium multilayer printed circuit board, computer, communication equipment, OA equipment, etc.

主要特性 / General properties

检测项目

Item |

单位

Unit |

检测条件

Test Condition |

规范值

Spec |

典型值

Typical Value |

玻璃化转变温度 Tg |

℃ |

DSC |

135±5 |

135.5 |

剥离强度 1oz Peel Strength |

N/mm |

288℃, 10S |

≥1.40 |

1.81 |

热应力 Thermal stress |

S |

288℃,solder dip |

> 10 |

120 s No delamination |

弯曲强度 Flexural Strength |

N/mm2 |

经向 LW |

≥415 |

580 |

纬向 CW |

≥345 |

485 |

燃烧性 Flammability |

- |

E 24/125 |

UL94V-0 |

V-0 |

表面电阻 Surface Resistivity |

MΩ |

After moisture |

≥1.0×104 |

5.16×107 |

体积电阻 VolumeResistivity |

MΩ·cm |

After moisture |

≥1.0×106 |

5.07×108 |

介电常数 Dielectric Constant |

- |

1 MHZ C 24/23/50 |

≤5.4 |

4.8 |

介质损耗角正切 Loss Tangent |

- |

1 MHZ C 24/23/50 |

≤0.035 |

0.015 |

耐电弧 Arc Resistance |

S |

D48/50 + D0.5/23 |

≥60 |

125 |

击穿电压 Dielectric Breakdown |

KV |

D48/50 + D0.5/23 |

≥40 |

58 |

吸水率 Moisture Absorption |

% |

D24/23 |

≤0.8 |

0.15 |

热分解温度 Td |

℃ |

Weight Loss 5% |

— |

310 |

CTE Z-axis |

Alpha 1 |

ppm / ℃ |

TMA |

— |

60 |

Alpha 2 |

ppm / ℃ |

— |

300 |

50 - 260 ℃ |

% |

— |

4.3 |

T288 |

min |

TMA |

— |

2 |

相比漏电起痕指数 CTI |

V |

IEC-60112 |

175 ~ 250 |

200 |

Specimen Thickness : 1.6mm ;

Explanation: C: Humidity conditioning; D: Immersion conditioning in distilled water ;

E: Temperature conditioning ;

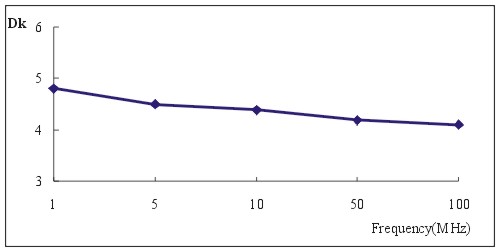

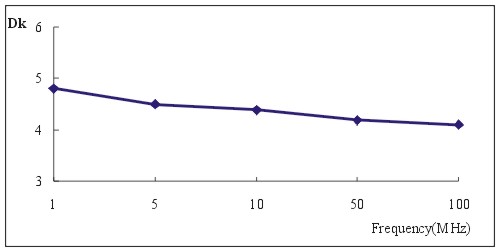

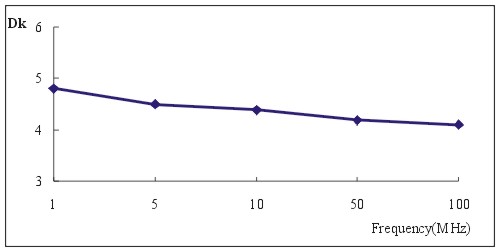

◆ 介电常数 / Dielectric constant

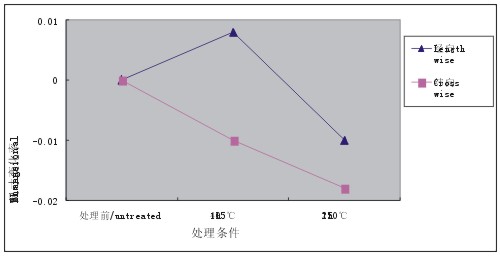

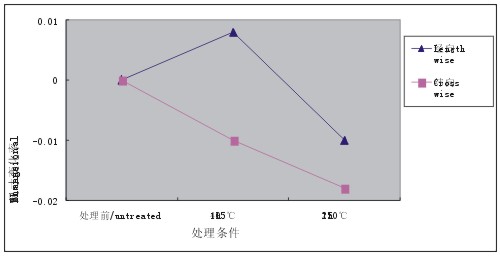

◆ 热处理后板材经纬向尺寸变化

Dimensional change in cross and length direction after heat treatment

产品系列 / Purchasing information

厚度 Thickness |

铜箔 Copper foil |

标准尺寸 Standard size |

0.10-3.2mm |

12um-105um |

37"×49" 、 41"×49" 、 43"×49" |

※ Other sheet size and thickness could be available upon request

◎ 半固化片介绍/Prepreg instruction

【H140AP (UV Prepreg)】

prepreg type |

Resin Content(%) |

Gel Time (sec/171℃) 胶化时间 |

Resin Flow 流动度 |

压合厚度 Cured thickness(mm/mil) |

R/C(%)

含量 |

Tolerance

公差 |

Nominal |

Range(±)mil |

% |

± |

S |

% |

mm |

mil |

mm |

mil |

7628HRC |

52 |

3 |

125 ± 20 |

30 ± 3 |

0.247 |

9.71 |

0.024 |

0.95 |

50 |

3 |

125 ± 20 |

29 ± 3 |

0.234 |

9.23 |

0.023 |

0.9 |

48 |

3 |

125 ± 20 |

28 ± 3 |

0.224 |

8.83 |

0.023 |

0.9 |

7628 |

45 |

3 |

130 ± 20 |

24 ± 3 |

0.207 |

8.15 |

0.020 |

0.8 |

43 |

3 |

130 ± 20 |

22 ± 3 |

0.197 |

7.76 |

0.020 |

0.8 |

1506 |

48 |

3 |

130 ± 20 |

29 ± 3 |

0.175 |

6.89 |

0.018 |

0.7 |

45 |

3 |

130 ± 20 |

28 ± 3 |

0.163 |

6.42 |

0.017 |

0.65 |

43 |

3 |

130 ± 20 |

25 ± 3 |

0.155 |

6.1 |

0.015 |

0.6 |

2116 |

58 |

3 |

120 ± 20 |

35 ± 3 |

0.145 |

5.71 |

0.015 |

0.6 |

57 |

3 |

120 ± 20 |

35 ± 3 |

0.142 |

5.59 |

0.014 |

0.55 |

55 |

3 |

120 ± 20 |

33 ± 3 |

0.134 |

5.28 |

0.014 |

0.55 |

53 |

3 |

120 ± 20 |

31 ± 3 |

0.127 |

5.00 |

0.013 |

0.5 |

50 |

3 |

120 ± 20 |

29 ± 3 |

0.119 |

4.69 |

0.013 |

0.5 |

1080 |

68 |

3 |

120 ± 20 |

44 ± 3 |

0.093 |

3.66 |

0.010 |

0.4 |

65 |

3 |

120 ± 20 |

42 ± 3 |

0.082 |

3.23 |

0.008 |

0.3 |

63 |

3 |

120 ± 20 |

39 ± 3 |

0.078 |

3.07 |

0.008 |

0.3 |

60 |

3 |

120 ± 20 |

37 ± 3 |

0.073 |

2.87 |

0.008 |

0.3 |

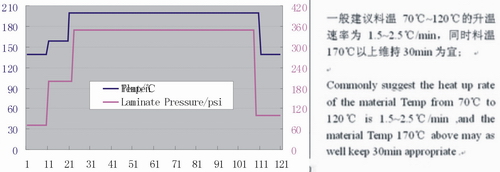

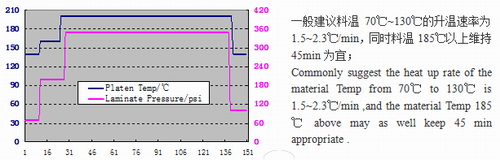

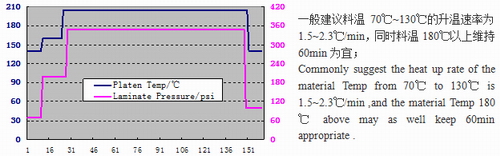

建议压制程式: Suggest cycle

【H1600A High CTI】

特性/ Features

Tg:135±5℃ (DSC)

优异的耐漏电起痕性,CTI≥600 / Excellent tracking resistance ,CTI ≥600

UV Blocking与 AOI兼容/UV Blocking and AOI compatible

优良的PCB加工性 / Good PCB processability

应用领域/ Applications

电源基板、电视机、电冰箱、洗衣机等。

Power base board、TV、refrigerator、 washing machine and etc.

主要特性 / General properties

检测项目

Item

|

单位

Unit

|

检测条件

Test Condition

|

规范值

Spec

|

典型值

Typical Value

|

玻璃化转变温度 Tg |

℃ |

DSC |

135±5 |

135.2 |

剥离强度 1oz Peel Strength |

N/mm |

288℃, 10S |

≥1.40 |

1.75 |

热应力 Thermal stress

|

S |

288℃,solder dip |

> 10 |

60 s No delamination |

弯曲强度 Flexural Strength |

N/mm2 |

经向 LW |

≥415 |

577 |

纬向 CW |

≥345 |

470 |

燃烧性 Flammability |

- |

E 24/125 |

UL94V-0 |

V-0 |

表面电阻 SurfaceResistivity

|

MΩ |

After moisture |

≥1.0×104 |

5.12×107 |

体积电阻 Volume Resistivity

|

MΩ·cm |

After moisture |

≥1.0×106 |

5.25×108 |

介电常数 Dielectric Constant

|

- |

1 MHZ C 24/23/50

|

≤5.4 |

4.6 |

介质损耗角正切 Loss Tangent

|

- |

1 MHZ C 24/23/50

|

≤0.035 |

0.015 |

耐电弧 Arc Resistance |

S |

D48/50 + D0.5/23 |

≥60 |

120 |

击穿电压Dielectric Breakdown

|

KV |

D48/50 + D0.5/23 |

≥40 |

57 |

吸水率 Moisture Absorption |

% |

D24/23 |

≤0.8 |

0.15 |

热分解温度 Td |

℃ |

Weight Loss 5% |

- |

310 |

CTE Z-axis |

Alpha 1 |

ppm / ℃ |

TMA |

- |

60 |

Alpha 2 |

ppm / ℃ |

- |

300 |

50 - 260 ℃ |

% |

- |

4.2 |

T288 |

min |

TMA |

- |

1 |

相比漏电起痕指数 CTI |

V |

IEC-60112 |

≥600 |

600 |

Specimen Thickness : 1.6mm ;

Explanation: C: Humidity conditioning; D: Immersion conditioning in distilled water ;

E: Temperature conditioning ;

◆ 介电常数 / Dielectric constant

◆ 热处理后板材经纬向尺寸变化

Dimensional change in cross and length direction after heat treatment

产品系列 / Purchasing information

厚度 Thickness |

铜箔 Copper foil |

标准尺寸 Standard size |

0.63-3.2mm |

12um-105um |

37"×49" 、 41"×49" 、 43"×49" |

※ Other sheet size and thickness could be available upon request

【H140-1 Lead-free Anti-CAF】

特性/ Features

Tg:135±5℃ (DSC)

UV Blocking与 AOI兼容可提高PCB生产效率

UV Blocking and AOI compatible,so as to increase productivity efficiency

优异的耐热性,Td ≥325℃,T288≥5min ,适合于无铅焊工艺;

High thermal performance,Td ≥325℃ ,T288≥5min,suitable for lead-free process。

应用领域/ Applications

适合于多层PCB、计算机及外围设备、通讯设备、办公自动设备、PCB无铅制程等。

Suitable for medium multilayer printed circuit board, computer, communication equipment, OA equipment,

lead-free PCB process etc.

主要特性 / General properties

检测项目

Item

|

单位

Unit

|

检测条件

Test Condition

|

规范值

Spec

|

典型值

Typical Value

|

玻璃化转变温度 Tg |

℃ |

DSC |

135±5 |

136.5 |

剥离强度 1oz Peel Strength |

N/mm |

288℃, 10S |

≥1.05 |

1.42 |

热应力 Thermal stress

|

S |

288℃,solder dip |

> 10 |

180 s No delamination |

弯曲强度 Flexural Strength |

N/mm2 |

经向 LW |

≥415 |

580 |

纬向 CW |

≥345 |

485 |

燃烧性 Flammability |

- |

E 24/125 |

UL94V-0 |

V-0 |

表面电阻 Surface Resistivity |

MΩ |

After moisture |

≥1.0×104 |

5.16×107 |

体积电阻 VolumeResistivity |

MΩ·cm |

After moisture |

≥1.0×106 |

5.07×108 |

介电常数 Dielectric Constant

|

- |

1 MHZ C 24/23/50

|

≤5.4 |

4.8 |

介质损耗角正切 Loss Tangent

|

- |

1 MHZ C 24/23/50

|

≤0.035 |

0.017 |

耐电弧 Arc Resistance |

S |

D48/50 + D0.5/23 |

≥60 |

125 |

击穿电压 Dielectric Breakdown

|

KV |

D48/50 + D0.5/23 |

≥40 |

58 |

吸水率 Moisture Absorption |

% |

D24/23 |

≤0.5 |

0.08 |

热分解温度 Td |

℃ |

Weight Loss 5% |

≥ 325 |

340 |

CTE Z-axis |

Alpha 1 |

ppm / ℃ |

TMA |

≤60 |

46 |

Alpha 2 |

ppm / ℃ |

≤300 |

260 |

50 - 260 ℃ |

% |

≤4.0 |

3.8 |

T288 |

min |

TMA |

≥ 5 |

30 |

相比漏电起痕指数 CTI |

V |

IEC-60112 |

175 ~ 250 |

200 |

Specimen Thickness : 1.6mm ;

Explanation: C: Humidity conditioning; D: Immersion conditioning in distilled water ;

E: Temperature conditioning ;

◆ 热压力容器蒸煮测试 / PCT(High pressure cooker test )

PCT (E-120℃/ 105KPa) |

Solder Dipping (288℃,10S) |

Normal FR-4 |

H140-1 |

30min |

OK |

OK |

60min |

OK |

OK |

120min |

NG |

OK |

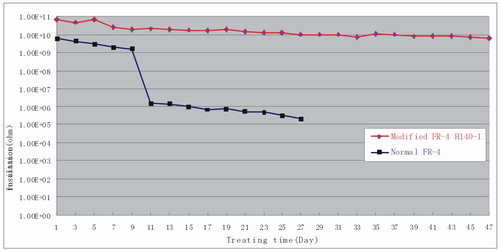

H140-1 覆铜板耐CAF性能测试

Test condition

a) Laminate: t1.6mm H/H (#7628*8ply)

b) Through hole wall to through hole wall distance:0.40

c) Drill diameter: 0.3mm

d) Condition: 85℃/85% RH 50V DC 1000h

测试结果见图1,。

The testing result as follows:

图1 改性FR-4(H140-1)覆铜板与普通FR-4覆铜板CAF测试图

结果表明,改性FR-4(H140-1)覆铜板在耐CAF方面相比普通FR-4有显著提升。

The result shows that improving FR-4(H140-1) has better anti-caf performance than normal FR-4

产品系列 / Purchasing informatio

厚度 Thickness |

铜箔 Copper foil |

标准尺寸 Standard size |

0.10-3.2mm |

12um-105um |

37"×49" 、 41"×49" 、 43"×49" |

※ Other sheet size and thickness could be available upon request

◎ 半固化片介绍/ Prepreg instruction

【H140-1 P (UV Prepreg)】

prepreg type |

Resin Content(%) |

Gel Time (sec/171℃) 胶化时间 |

Resin Flow

流动度 |

压合厚度 Cured thickness(mm/mil) |

R/C(%)含量 |

Tolerance

公差 |

Nominal |

Range(±)mil |

% |

± |

S |

% |

mm |

mil |

mm |

mil |

7628HRC |

52 |

3 |

100±20 |

30±3 |

0.227 |

8.91 |

0.023 |

0.90 |

50 |

3 |

100±20 |

29±3 |

0.214 |

8.43 |

0.022 |

0.85 |

48 |

3 |

100±20 |

28±3 |

0.206 |

8.11 |

0.020 |

0.8 |

7628 |

45 |

3 |

105±20 |

24±3 |

0.192 |

7.56 |

0.019 |

0.75 |

43 |

3 |

105±20 |

22±3 |

0.183 |

7.20 |

0.018 |

0.7 |

1506 |

48 |

3 |

105±20 |

29±3 |

0.162 |

6.38 |

0.017 |

0.65 |

45 |

3 |

105±20 |

28±3 |

0.151 |

5.94 |

0.015 |

0.6 |

43 |

3 |

105±20 |

25±3 |

0.145 |

5.71 |

0.015 |

0.6 |

2116 |

58 |

3 |

110±20 |

35±3 |

0.134 |

5.28 |

0.014 |

0.55 |

57 |

3 |

110±20 |

35±3 |

0.13 |

5.12 |

0.013 |

0.5 |

55 |

3 |

110±20 |

33±3 |

0.123 |

4.84 |

0.013 |

0.5 |

53 |

3 |

110±20 |

31±3 |

0.117 |

4.61 |

0.011 |

0.45 |

50 |

3 |

110±20 |

29±3 |

0.108 |

4.25 |

0.011 |

0.45 |

1080 |

68 |

3 |

110±20 |

44±3 |

0.084 |

3.31 |

0.008 |

0.3 |

65 |

3 |

110±20 |

42±3 |

0.076 |

2.99 |

0.008 |

0.3 |

63 |

3 |

110±20 |

39±3 |

0.071 |

2.80 |

0.008 |

0.3 |

60 |

3 |

110±20 |

37±3 |

0.065 |

2.56 |

0.008 |

0.3 |

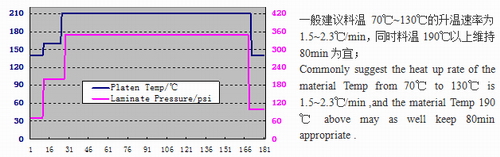

建议压制程式: Suggest cycle

【H150(LF) Lead-free】

特性/ Features

Tg≥150℃ (DSC)

UV Blocking与 AOI兼容可提高PCB生产效率

UV Blocking and AOI compatible,so as to increase productivity efficiency

优异的耐热性,Td ≥325℃,T288≥5min ,适合于无铅焊工艺;

High thermal performance,Td ≥325℃ ,T288≥5min,suitable for lead-free process。

应用领域/ Applications

适合于多层PCB、计算机及外围设备、通讯设备、办公自动设备、PCB无铅制程等。

Suitable for medium multilayer printed circuit board, computer, communication equipment, OA equipment,

lead-free PCB process etc.

主要特性 / General properties

检测项目

Item

|

单位

Unit

|

检测条件

Test Condition

|

规范值

Spec

|

典型值

Typical Value

|

玻璃化转变温度 Tg |

℃ |

DSC |

≥ 150 |

154.5 |

剥离强度 1oz Peel Strength |

N/mm |

288℃, 10S |

≥1.05 |

1.41 |

热应力 Thermal stress

|

S |

288℃,solder dip |

> 10 |

180s No delamination |

弯曲强度 Flexural Strength |

N/mm2 |

经向 LW |

≥415 |

570 |

纬向 CW |

≥345 |

465 |

燃烧性 Flammability |

- |

E 24/125 |

UL94V-0 |

V-0 |

表面电阻 Surface Resistivity |

MΩ |

After moisture |

≥1.0×104 |

6.12×107 |

体积电阻 VolumeResistivity |

MΩ·cm |

After moisture |

≥1.0×104 |

6.25×108 |

介电常数 Dielectric Constant

|

- |

1 MHZ C 24/23/50

|

≤5.4 |

4.7 |

介质损耗角正切 Loss Tangent

|

- |

1 MHZ C 24/23/50

|

≤0.035 |

0.016 |

耐电弧 Arc Resistance |

S |

D48/50 + D0.5/23 |

≥60 |

125 |

击穿电压 Dielectric Breakdown

|

KV |

D48/50 + D0.5/23 |

≥40 |

57 |

吸水率 Moisture Absorption |

% |

D24/23 |

≤0.5 |

0.10 |

热分解温度 Td |

℃ |

Weight Loss 5% |

≥325 |

348 |

CTE Z-axis |

Alpha 1 |

ppm / ℃ |

TMA |

≤ 60 |

55 |

Alpha 2 |

ppm / ℃ |

≤ 300 |

276 |

50 - 260 ℃ |

% |

≤ 3.5 |

3.3 |

T288 |

min |

TMA |

≥5 |

35 |

相比漏电起痕指数 CTI |

V |

IEC-60112 |

175 ~ 250 |

200 |

Specimen Thickness : 1.6mm ;

Explanation: C: Humidity conditioning; D: Immersion conditioning in distilled water ;

E: Temperature conditioning ;

◆ 热压力容器蒸煮测试 / PCT(High pressure cooker test )

PCT (E-120℃/ 105KPa) |

Solder Dipping (288℃,10S) |

Normal FR-4 |

H150(LF) |

30min |

OK |

OK |

60min |

OK |

OK |

120min |

NG |

OK |

◆ 使用建议 / Suggestion for use

1、使用前请进行烘板处理:150 ℃、2h 。

Please baking the Laminate at 150 ℃、2 hours before using .

2、由于层间结合力较常规FR-4差,钻孔加工时请注意。

钻孔参数主要取决于孔的大小、内层厚度、层数、铜箔厚度和叠层厚度。

以典型的0.4~1.0mm钻嘴孔径为例,其建议钻孔参数如下:

钻刀转速:45~105 KRPM , 进刀速度: 50~150 IPM

缩刀速度:500~1000 IPM, 建议使用次数:1500 HITS

叠层高度:≤2pnls(2~6layers), 1pnl(≥8layers)

覆层材料:0.2mm Aluminum

产品系列 / Purchasing informatio

厚度 Thickness |

铜箔 Copper foil |

标准尺寸 Standard size |

0.10-3.2mm |

12um-105um |

37"×49" 、 41"×49" 、 43"×49" |

※ Other sheet size and thickness could be available upon request

半固化片介绍/ Prepreg instruction

【H150 P(LF) (UV Prepreg)】

prepreg type |

Resin Content(%) |

Gel Time (sec/171℃) 胶化时间 |

Resin Flow

流动度 |

压合厚度 Cured thickness(mm/mil) |

R/C(%)

含量 |

Tolerance 公差 |

Nominal |

Range(±)mil |

% |

± |

S |

% |

mm |

mil |

mm |

mil |

7628HRC |

52 |

3 |

100±20 |

30±3 |

0.231 |

9.09 |

0.022 |

0.85 |

50 |

3 |

100±20 |

29±3 |

0.22 |

8.66 |

0.022 |

0.85 |

48 |

3 |

100±20 |

28±3 |

0.21 |

8.27 |

0.020 |

0.8 |

7628 |

45 |

3 |

105±20 |

24±3 |

0.195 |

7.68 |

0.019 |

0.75 |

43 |

3 |

105±20 |

22±3 |

0.186 |

7.32 |

0.018 |

0.7 |

1506 |

48 |

3 |

105±20 |

29±3 |

0.164 |

6.46 |

0.017 |

0.65 |

45 |

3 |

105±20 |

28±3 |

0.153 |

6.02 |

0.015 |

0.6 |

43 |

3 |

105±20 |

25±3 |

0.146 |

5.75 |

0.015 |

0.6 |

2116 |

58 |

3 |

105±20 |

35±3 |

0.136 |

5.35 |

0.014 |

0.55 |

57 |

3 |

105±20 |

35±3 |

0.132 |

5.20 |

0.013 |

0.5 |

55 |

3 |

105±20 |

33±3 |

0.125 |

4.92 |

0.013 |

0.5 |

53 |

3 |

105±20 |

31±3 |

0.119 |

4.69 |

0.011 |

0.45 |

50 |

3 |

105±20 |

29±3 |

0.11 |

4.33 |

0.011 |

0.45 |

1080 |

68 |

3 |

105±20 |

44±3 |

0.086 |

3.39 |

0.008 |

0.3 |

65 |

3 |

105±20 |

42±3 |

0.077 |

3.03 |

0.008 |

0.3 |

63 |

3 |

105±20 |

39±3 |

0.073 |

2.87 |

0.008 |

0.3 |

60 |

3 |

105±20 |

37±3 |

0.066 |

2.60 |

0.008 |

0.3 |

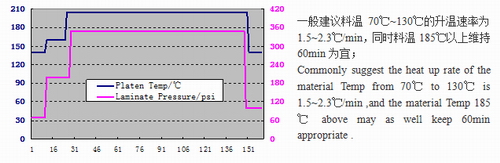

建议压制程式: Suggest cycle

【H1170 Lead-free】

特性/ Features

Tg≥170℃ (DSC)

UV Blocking与 AOI兼容可提高PCB生产效率

UV Blocking and AOI compatible,so as to increase productivity efficiency

优异的耐热性,Td ≥340℃,T288≥15min ,适合于无铅焊工艺;

High thermal performance,Td ≥340℃ ,T288≥15min,suitable for lead-free process。

应用领域/ Applications

适合于高多层PCB、计算机及外围设备、通讯设备、办公自动设备、PCB无铅制程等。

Suitable for high-count layer PCB, computer, communication equipment, OA equipment,

lead-free PCB process etc.

主要特性 / General properties

检测项目

Item

|

单位

Unit

|

检测条件

Test Condition

|

规范值

Spec

|

典型值

Typical Value

|

玻璃化转变温度 Tg |

℃ |

DSC |

≥ 170 |

175.2 |

剥离强度 1oz Peel Strength |

N/mm |

288℃, 10S |

≥1.05 |

1.41 |

热应力 Thermal stress

|

S |

288℃,solder dip |

≥10 |

180 s No delamination |

弯曲强度 Flexural Strength |

N/mm2 |

经向 LW |

≥415 |

580 |

纬向 CW |

≥345 |

482 |

燃烧性 Flammability |

- |

E 24/125 |

UL94V-0 |

V-0 |

表面电阻 Surface Resistivity |

MΩ |

After moisture |

≥1.0×104 |

2.52×107 |

体积电阻 VolumeResistivity |

MΩ·cm |

After moisture |

≥1.0×104 |

3.21×108 |

介电常数 Dielectric Constant

|

- |

1 MHZ C 24/23/50

|

≤5.4 |

4.7 |

介质损耗角正切 Loss Tangent

|

- |

1 MHZ C 24/23/50

|

≤0.035 |

0.016 |

耐电弧 Arc Resistance |

S |

D48/50 + D0.5/23 |

≥60 |

122 |

击穿电压 Dielectric Breakdown

|

KV |

D48/50 + D0.5/23 |

≥40 |

58 |

吸水率 Moisture Absorption |

% |

D24/23 |

≤0.5 |

0.10 |

热分解温度 Td |

℃ |

Weight Loss 5% |

≥340 |

347 |

CTE Z-axis |

Alpha 1 |

ppm / ℃ |

TMA |

≤60 |

45 |

Alpha 2 |

ppm / ℃ |

≤300 |

270 |

50 - 260 ℃ |

% |

≤3.0 |

2.9 |

T288 |

min |

TMA |

≥15 |

30 |

相比漏电起痕指数 CTI |

V |

IEC-60112 |

175 ~ 250 |

200 |

Specimen Thickness : 1.6mm ;

Explanation: C: Humidity conditioning; D: Immersion conditioning in distilled water ;

E: Temperature conditioning ;

【H1170 Lead-free】

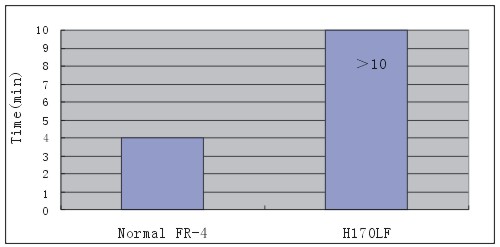

◆优异的耐热性 / Excellent thermal stress resistance

产品系列 / Purchasing informati

厚度 Thickness |

铜箔 Copper foil |

标准尺寸 Standard size |

0.10-3.2mm |

12um-105um |

37"×49" 、 41"×49" 、 43"×49" |

半固化片介绍/ Prepreg instruction

【H1170 P (UV Prepreg)】

prepreg type |

Resin Content(%) |

Gel Time (sec/171℃)

胶化时间 |

Resin Flow

流动度 |

压合厚度 Cured thickness(mm/mil) |

R/C(%)

含量 |

Tolerance

公差 |

Nominal |

Range(±)mil |

% |

± |

S |

% |

mm |

mil |

mm |

mil |

7628HRC |

52 |

3 |

100±20 |

30±3 |

0.234 |

9.21 |

0.022 |

0.85 |

50 |

3 |

110±20 |

29±3 |

0.223 |

8.78 |

0.022 |

0.85 |

48 |

3 |

110±20 |

28±3 |

0.212 |

8.35 |

0.020 |

0.8 |

7628 |

45 |

3 |

115±20 |

24±3 |

0.197 |

7.76 |

0.019 |

0.75 |

43 |

3 |

115±20 |

22±3 |

0.188 |

7.40 |

0.018 |

0.7 |

1506 |

48 |

3 |

115±20 |

29±3 |

0.166 |

6.54 |

0.017 |

0.65 |

45 |

3 |

115±20 |

28±3 |

0.155 |

6.10 |

0.015 |

0.6 |

43 |

3 |

115±20 |

25±3 |

0.148 |

5.83 |

0.015 |

0.6 |

2116 |

58 |

3 |

115±20 |

35±3 |

0.138 |

5.43 |

0.014 |

0.55 |

57 |

3 |

115±20 |

35±3 |

0.136 |

5.35 |

0.013 |

0.5 |

55 |

3 |

115±20 |

33±3 |

0.127 |

5.00 |

0.013 |

0.5 |

53 |

3 |

115±20 |

31±3 |

0.12 |

4.72 |

0.011 |

0.45 |

50 |

3 |

115±20 |

29±3 |

0.111 |

4.37 |

0.011 |

0.45 |

1080 |

68 |

3 |

115±20 |

44±3 |

0.087 |

3.43 |

0.008 |

0.3 |

65 |

3 |

115±20 |

42±3 |

0.077 |

3.03 |

0.008 |

0.3 |

63 |

3 |

115±20 |

39±3 |

0.074 |

2.91 |

0.008 |

0.3 |

60 |

3 |

115±20 |

37±3 |

0.067 |

2.64 |

0.008 |

0.3 |

建议压制程式: Suggest cycle

【H140H Halogen-free】

特性/ Features

无卤产品,Halogen-free product, Tg:135±5℃

阻燃性达到UL94V-0 / Flammability UL 94V-0 .

可依需求提供高CTI的无卤板材/ High CTI Halogen-free product available upon request (CTI 600)

应用领域/ Applications

手机、电脑、通讯设备、仪器仪表、摄像机、电视机等。

Mobile phone, Computer,Communication equipment , Instrumentation, VCR,Television, etc.

主要特性 / General properties

检测项目

Item

|

单位

Unit

|

检测条件

Test Condition

|

规范值

Spec

|

典型值

Typical Value

|

玻璃化转变温度 Tg |

℃ |

DSC |

135±5 |

133 |

剥离强度 1oz Peel Strength |

N/mm |

288℃, 10S |

≥1.05 |

1.42 |

热应力 Thermal stress

|

S |

288℃,solder dip |

> 10 |

180s No delamination |

弯曲强度 Flexural Strength |

N/mm2 |

经向 LW |

≥415 |

580 |

纬向 CW |

≥345 |

475 |

燃烧性 Flammability

|

- |

E 24/125 |

UL94V-0 |

V-0 |

表面电阻 Surface Resistivity |

MΩ |

After moisture |

≥1.0×104 |

5.21×107 |

体积电阻 VolumeResistivity |

MΩ·cm |

After moisture |

≥1.0×106 |

5.10×108 |

介电常数 Dielectric Constant

|

- |

1 MHZ C 24/23/50

|

≤5.4 |

4.6 |

介质损耗角正切 Loss Tangent

|

- |

1 MHZ C 24/23/50

|

≤0.035 |

0.015 |

耐电弧 Arc Resistance |

S |

D48/50 + D0.5/23 |

≥60 |

120 |

击穿电压 Dielectric Breakdown

|

KV |

D48/50 + D0.5/23 |

≥40 |

57 |

吸水率 Moisture Absorption |

% |

D24/23 |

≤0.8 |

0.16 |

热分解温度 Td |

℃ |

Weight Loss 5% |

≥325 |

358 |

T288 (不覆铜) |

min |

TMA |

≥5 |

12 |

Z-CTE /50 - 260 ℃ |

% |

TMA |

≤4.0 |

3.9 |

相比漏电起痕指数 CTI |

V |

IEC-60112 |

175 ~ 250 |

200 |

卤素含量

Halogen content

|

Cl |

ppm |

EDX-GP |

≤900 |

310 |

Br |

ppm |

≤900 |

30 |

Cl+Br |

ppm |

≤1500 |

350 |

Specimen Thickness : 1.6mm ;

Explanation: C: Humidity conditioning; D: Immersion conditioning in distilled water;

E: Temperature conditioning ;

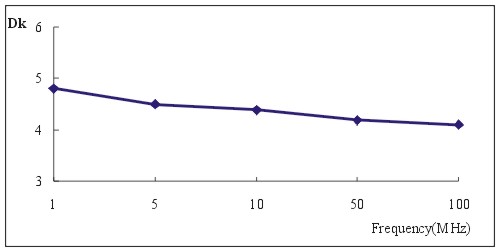

◆ 介电常数 / Dielectric constant

◆ 使用建议 / Suggestion for use

1、使用前请进行烘板处理:150 ℃、2h 。

Please baking the Laminate at 150 ℃、2 hours before using .

2、由于层间结合力较常规FR-4差,钻孔加工时请注意。

钻孔参数主要取决于孔的大小、内层厚度、层数、铜箔厚度和叠层厚度。

以典型的0.4~1.0mm钻嘴孔径为例,其建议钻孔参数如下:

钻刀转速:45~105 KRPM , 进刀速度: 50~150 IPM

缩刀速度:500~1000 IPM, 建议使用次数:1500 HITS

叠层高度:≤2pnls(2~6layers), 1pnl(≥8layers)

覆层材料:0.2mm Aluminum

Please pay attention to the machining for the interbedded energy is lower than the normal FR-4 .

Drilling parameters are mainly dependent on hole size, layer thickness, layer number, copper thickness and

stack height. The following drilling parameters are for reference only. Typical drilling parameters for 0.4~1.0 mm drills are as follows:

Spindle speed: 45~105 KRPM Feed rate: 50~150 IPM

Retract rate: 500~1000 IPM sug. hit count: 1500 HITS

Stack height: ≤2pnls(2~6layers), 1pnl(≥8layers) Entry Material: 0.2mm Aluminum

产品系列 / Purchasing informatio

厚度 Thickness |

铜箔 Copper foil |

标准尺寸 Standard size |

0.10-3.2mm |

12um-105um |

37"×49" 、 41"×49" 、 43"×49" |

※ Other sheet size and thickness could be available upon request

半固化片介绍/ Prepreg instruction

【H140H P (UV Prepreg)】

prepreg type |

Resin Content(%) |

Gel Time (sec/171℃) 胶化时间 |

Resin Flow

流动度 |

压合厚度 Cured thickness(mm/mil) |

R/C(%)

含量 |

Tolerance

公差 |

Nominal |

Range(±)mil |

% |

± |

S |

% |

mm |

mil |

mm |

mil |

7628HRC |

52 |

3 |

130±20 |

30±3 |

0.227 |

8.93 |

0.023 |

0.90 |

50 |

3 |

135±20 |

29±3 |

0.217 |

8.41 |

0.022 |

0.85 |

48 |

3 |

135±20 |

28±3 |

0.206 |

8.11 |

0.020 |

0.8 |

7628 |

45 |

3 |

140±20 |

24±3 |

0.192 |

7.56 |

0.019 |

0.75 |

43 |

3 |

140±20 |

22±3 |

0.183 |

7.20 |

0.018 |

0.7 |

1506 |

48 |

3 |

140±20 |

29±3 |

0.162 |

6.38 |

0.017 |

0.65 |

45 |

3 |

140±20 |

28±3 |

0.151 |

5.94 |

0.015 |

0.6 |

43 |

3 |

140±20 |

25±3 |

0.145 |

5.71 |

0.015 |

0.6 |

2116 |

58 |

3 |

140±20 |

35±3 |

0.134 |

5.28 |

0.014 |

0.55 |

57 |

3 |

140±20 |

35±3 |

0.13 |

5.12 |

0.013 |

0.5 |

55 |

3 |

140±20 |

33±3 |

0.123 |

4.84 |

0.013 |

0.5 |

53 |

3 |

140±20 |

31±3 |

0.117 |

4.61 |

0.011 |

0.45 |

50 |

3 |

140±20 |

29±3 |

0.108 |

4.25 |

0.011 |

0.45 |

1080 |

68 |

3 |

140±20 |

44±3 |

0.084 |

3.31 |

0.008 |

0.3 |

65 |

3 |

140±20 |

42±3 |

0.076 |

2.99 |

0.008 |

0.3 |

63 |

3 |

140±20 |

39±3 |

0.071 |

2.80 |

0.008 |

0.3 |

60 |

3 |

140±20 |

37±3 |

0.065 |

2.56 |

0.008 |

0.3 |

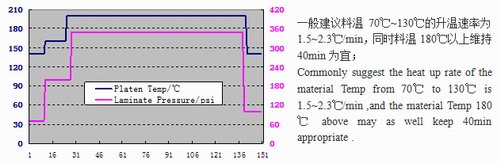

建议压制程式: Suggest cycle

【H155H Halogen-free】

特性/ Features

无卤产品,Halogen-free product, Tg:150±5℃℃

阻燃性达到UL94V-0 / Flammability UL 94V-0 .

可依需求提供高CTI的无卤板材/ High CTI Halogen-free product available upon request (CTI 600)

应用领域/ Applications

手机、电脑、通讯设备、仪器仪表、摄像机、电视机等。

Mobile phone, Computer,Communication equipment , Instrumentation, VCR,Television, etc.

主要特性 / General properties

检测项目

Item

|

单位

Unit

|

检测条件

Test Condition

|

规范值

Spec

|

典型值

Typical Value

|

玻璃化转变温度 Tg |

℃ |

DSC |

150±5 ℃ |

150.2 |

剥离强度 1oz Peel Strength |

N/mm |

288℃, 10S |

≥1.05 |

1.42 |

热应力 Thermal stress

|

S |

288℃,solder dip |

> 10 |

180 s No delamination |

弯曲强度 Flexural Strength |

N/mm2 |

经向 LW |

≥415 |

580 |

纬向 CW |

≥345 |

475 |

燃烧性 Flammability

|

- |

E 24/125 |

UL94V-1 |

V-0 |

表面电阻 Surface Resistivity |

MΩ |

After moisture |

≥1.0×104 |

5.21×107 |

体积电阻 VolumeResistivity |

MΩ·cm |

After moisture |

≥1.0×106 |

5.10×108 |

介电常数 Dielectric Constant

|

- |

1 MHZ C 24/23/50

|

≤5.4 |

4.6 |

介质损耗角正切 Loss Tangent

|

- |

1 MHZ C 24/23/50

|

≤0.035 |

0.015 |

耐电弧 Arc Resistance |

S |

D48/50 + D0.5/23 |

≥60 |

120 |

击穿电压 Dielectric Breakdown

|

KV |

D48/50 + D0.5/23 |

≥40 |

57 |

吸水率 Moisture Absorption |

% |

D24/23 |

≤0.8 |

0.16 |

热分解温度 Td |

℃ |

Weight Loss 5% |

≥325 |

358 |

T288 (不覆铜) |

min |

TMA |

≥5 |

30 |

Z-CTE /50 - 260 ℃ |

% |

TMA |

≤4.0 |

3.5 |

相比漏电起痕指数 CTI |

V |

IEC-60112 |

175 ~ 250 |

200 |

卤素含量

Halogen content

|

Cl |

ppm |

EDX-GP

|

≤900 |

310 |

Br |

ppm |

≤900 |

30 |

Cl+Br |

ppm |

≤1500 |

350 |

Specimen Thickness : 1.6mm ;

Explanation: C: Humidity conditioning; D: Immersion conditioning in distilled water;

E: Temperature conditioning ;

◆ 介电常数 / Dielectric constant

◆ 使用建议 / Suggestion for use

1、使用前请进行烘板处理:150 ℃、2h 。

Please baking the Laminate at 150 ℃、2 hours before using .

2、由于层间结合力较常规FR-4差,钻孔加工时请注意。

钻孔参数主要取决于孔的大小、内层厚度、层数、铜箔厚度和叠层厚度。

以典型的0.4~1.0mm钻嘴孔径为例,其建议钻孔参数如下:

钻刀转速:45~105 KRPM , 进刀速度: 50~150 IPM

缩刀速度:500~1000 IPM, 建议使用次数:1500 HITS

叠层高度:≤2pnls(2~6layers), 1pnl(≥8layers)

覆层材料:0.2mm Aluminum

Please pay attention to the machining for the interbedded energy is lower than the normal FR-4 .

Drilling parameters are mainly dependent on hole size, layer thickness, layer number, copper thickness and

stack height. The following drilling parameters are for reference only. Typical drilling parameters for 0.4~1.0 mm drills are as follows:

Spindle speed: 45~105 KRPM Feed rate: 50~150 IPM

Retract rate: 500~1000 IPM sug. hit count: 1500 HITS

Stack height: ≤2pnls(2~6layers), 1pnl(≥8layers) Entry Material: 0.2mm Aluminum

产品系列 / Purchasing informatio

厚度 Thickness |

铜箔 Copper foil |

标准尺寸 Standard size |

0.10-3.2mm |

12um-105um |

37"×49" 、 41"×49" 、 43"×49" |

※ Other sheet size and thickness could be available upon request

半固化片介绍/ Prepreg instruction

【H155H P (UV Prepreg)】

prepreg type |

Resin Content(%) |

Gel Time (sec/171℃) 胶化时间 |

Resin Flow 流动度 |

压合厚度 Cured thickness(mm/mil) |

R/C(%)

含量 |

Tolerance

公差 |

Nominal |

Range(±)mil |

% |

± |

S |

% |

mm |

mil |

mm |

mil |

7628HRC |

52 |

3 |

105±20 |

30±3 |

0.227 |

8.93 |

0.023 |

0.90 |

50 |

3 |

105±20 |

29±3 |

0.217 |

8.41 |

0.022 |

0.85 |

48 |

3 |

110±20 |

28±3 |

0.206 |

8.11 |

0.020 |

0.8 |

7628 |

45 |

3 |

110±20 |

24±3 |

0.192 |

7.56 |

0.019 |

0.75 |

43 |

3 |

110±20 |

22±3 |

0.183 |

7.20 |

0.018 |

0.7 |

1506 |

48 |

3 |

110±20 |

29±3 |

0.162 |

6.38 |

0.017 |

0.65 |

45 |

3 |

110±20 |

28±3 |

0.151 |

5.94 |

0.015 |

0.6 |

43 |

3 |

110±20 |

25±3 |

0.145 |

5.71 |

0.015 |

0.6 |

2116 |

58 |

3 |

110±20 |

35±3 |

0.134 |

5.28 |

0.014 |

0.55 |

57 |

3 |

110±20 |

35±3 |

0.13 |

5.12 |

0.013 |

0.5 |

55 |

3 |

110±20 |

33±3 |

0.123 |

4.84 |

0.013 |

0.5 |

53 |

3 |

110±20 |

31±3 |

0.117 |

4.61 |

0.011 |

0.45 |

50 |

3 |

110±20 |

29±3 |

0.108 |

4.25 |

0.011 |

0.45 |

1080 |

68 |

3 |

110±20 |

44±3 |

0.084 |

3.31 |

0.008 |

0.3 |

65 |

3 |

110±20 |

42±3 |

0.076 |

2.99 |

0.008 |

0.3 |

63 |

3 |

110±20 |

39±3 |

0.071 |

2.80 |

0.008 |

0.3 |

60 |

3 |

110±20 |

37±3 |

0.065 |

2.56 |

0.008 |

0.3 |

建议压制程式: Suggest cycle

覆铜板厚度公差表CCL thickness and tolerance list

标准厚度 mm

standard thickness |

厚度公差 mm / tolerance |

Class B/L 级 |

Class C/M 级 |

0.025 ~ 0.119 |

±0.018 |

±0.013 |

0.120 ~ 0.164 |

±0.025 |

±0.018 |

0.165 ~ 0.299 |

±0.038 |

±0.025 |

0.300 ~ 0.499 |

±0.050 |

±0.038 |

0.500 ~ 0.785 |

±0.064 |

±0.050 |

0.786 ~ 1.039 |

±0.100 |

±0.075 |

1.040 ~ 1.674 |

±0.130 |

±0.075 |

1.675 ~ 2.564 |

±0.180 |

±0.100 |

2.565 ~ 3.579 |

±0.230 |

±0.130 |

3.580 ~ 6.350 |

±0.300 |

±0.150 |

※ 一般情况下,华正电子依照二级厚度公差(B/L级)要求接单作业,加严厚度公差(三级公差C/M级)或特殊厚度公差要求可协商解决。

Commonly , we will accept the order form according to the Class B/L , the Class C/M or other special tolerance could be available upon request.

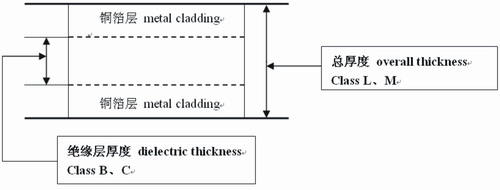

※ Class B、C表示不含铜箔的板材厚度; Class L、M为含铜箔在内的板材厚度;

Class B、C figure the dielectric thickness ;Class L、M figure the overall thickness;

如下图 / As follows:

半固化片储存条件:Prepreg Storage Condition

温度≤20℃、湿度≤50%,保存时间3个月;温度≤5℃、密封条件下,保存时间6个月.

T≤20℃& ≤50%RH,Within 3 months; T≤5 ℃ Within 6 months (seal condition).

在上述要求内,我司可立即安排PP送样;若有特殊要求,由供需双方商定。Follow upwards condition,Our company will arrange sample immediately. We can negotiation if you have special requirement.

|