|

| 制造公司 |

建滔基层板控股有限公司 |

| 公司网站 |

http://www.kingboard.com |

| 公司简介 |

建滔铜箔集团有限公司致力于电解铜箔的生产,在中国广东省的佛冈与连州分设两个生产基地。总投资为22亿港币,年产电解铜箔72000吨,现有职员1500人。公司经历了十多年的发展已经成为国内同行业中生产规模最大、自动化程度最高、品种最齐全,工艺最先进的电解铜箔生产基地。铜箔厚度范围:8~140μm;产品除满足国内需求外,还远销意大利、美国,加拿大等地。

公司致力于打造一个“和谐、高效、求实、创新”的团队,发扬建滔精神,实现企业目标。产品研发、生产制造和企业管理等各类专业技术人才济济一堂,传承着十多年的电解铜箔制造经验。公司产品有供覆铜面板和PCB生产专用的粗化铜箔和涂胶铜箔;并能生产市场所需的各种新型铜箔,如电池铜箔、甚低峰值铜箔、双面处理铜箔和高温高延铜箔等。

“以先进的工艺和设备,科学化的管理手段,以人为本的管理理念,创造完美的品质,全心全意满足客户,追求卓越,不断创新。”作为公司的质量方针。全方位打造广大客户需要的产品。产品以卓越的外观质量和内在性能赢得了众多客户的青睐,公司高度重视环保,以“清洁生产,循环经济”为宗旨,建立节能环保机制,争取实现无污染的半封闭生产的目标,成为绿色环保企业。并顺利通过了ISO14001认证。

为了适应可持续发展的要求,公司不断超越自我,创造未来,致力于开发高、新、特、精的新型铜箔,以新的体制,新的姿态面对市场的挑战,继续为铜箔事业开拓创新。

Brief Introduction

Kingboard Copper Foil Holdings Limited, with electrolyzed copper foils as its main product, now has two producing bases in Fogang and LianzhouofGuangdong Province. With a total investment of 2.2 billion HK dollars, the annual production of electrolyzed copper foils of 72,000 tons, and the registered stuff number of 1,500, Kingboard has, after dozens of years' development, become an all-round top company in the electrolyzed copper foil field, in terms of manufacture scale, automatic level, product variety and processing technics. Its copper foils,with thickness ranging from 8 to 140 μm, It is not only popular at Mainland, but also gains reputation and market in overseas,such as Italy, America, Canada, etc.

Kingboard, as a compact group, has been practicing the spirit of "harmonious, effective,

factualistic, innovative" to realize enterprise targets. Here, including diversified professionals specialized in product R&D, producing process and enterprise management gather and share

experience of electrolyzed copper foil manufacturing. Besides its main products of rough copper foils and gelatinized copper foils which are specially used for the manufacture of copper-cover panels and PCBs, Kingboard also owns capacities for manufacturing new-style copper foils, such as battery copper foils, extremely low peak value copper foils, two-sided processing copper foils, high-temperature and high-extensibility copper foils, etc.

"Through advanced technics and equipments, scientific managing methods, human-oriented managing concepts, to create perfect quality and achieve maximized satisfaction in constant innovation." Based on these quality principles, Kingboard has made its products popular with enormous customers both for their appearance and performance. Besides, Kingboard has always been pay attention to great importance to environment protection. Following the principles of "circulation and economization", mechanism of energy saving and environmental protection has been established. On the way to realizing harmless and semi-closed manufacture, Kingboard has successfully passed ISO14001 attestation, and is now near its goal of becoming an environmentally friendly enterprise .

In order to adapt to the new request of continuable development, Kingboard is now making every effort to exploit new kinds of copper foils that are excellent, novel, special and delicate in quality. It is now facing market challenges with a brand-new image as well as a renewed system, ready to make its own contributions to the copper foil industry. |

铜箔产品一览表(1) Copper Foil Products List(1)

铜箔类型

Type |

产品型号

Model |

铜箔厚度Thickness |

产品特性

Character |

产品用途

Application |

粗化铜箔Abrading copper foil |

STD |

12 |

高级单面处理电解铜箔,厚度均匀、无针孔、具有良好的高结合力和高温抗剥、抗拉性能,有效的增大了板材的热稳定性和导电性能,独特的 Cu-Zn 合金处理改善铜箔的抗热及抗化学性。

Advanced single-side treated with electrolytic copper foil, uniform thickness, and pinhole- free. Strong binding force, anti- stripping and anti- stretching performance at high temperature. Effectively increased thermal stability and the conductive properties of the sheet metal. Unique Cu-Zn alloy processing to improve the heat- and chemical- resistance of copper foil |

适用于双官能基四官能基之环氧树脂基板中层数 MLB (多层板)及各种常用的板材使用。

Applicable to di- and tetra-functional groups of epoxy resin substrate, middle-layers MLB and other commonly used plates

|

18 |

35 |

50 |

70 |

105 |

140 |

普通涂胶铜箔Ordinary Adhesive coated foil |

ACC |

18 |

采用酚醛树脂改性的聚乙烯醇缩醛树脂做胶粘剂, 胶膜均匀、无杂质、无渗透孔,有更好的耐浸焊和抗剥性能,与纸基结合具有优秀的耐热性和阻燃性

The phenolic resin modified polyvinyl acetal resin is used as adhesive. Uniform film with no impurities and no penetration hole. Better dip-soldering resistance and anti-peeling performance. Excellent heat resistance and flame retardance when combined with paper-base and flame relardant |

适用于中、低端民用电子产品及办公自动化设备的电源基板

Applicable to the power substrate of low- and middle-end civil electronic products and automatic office equipment

|

25 |

35 |

70 |

CTI 涂胶铜箔

CTI Adhesive

coated foil |

CTI |

35 |

除了具有普通涂胶箔良好的耐浸和抗剥性能以外 , 并且具有( 600V )无漏电起痕特性。

In addition to the good dip-soldering resistance and anti-peeling performance of the ordinary adhesive coated foil , no proof tracking under high-voltage (600V) is also featured |

适用于高端民用电子产品及办公自动化设备的电源基板

Applicable to di- and tetra-functional groups of epoxy resin substrate, middle-layers MLB and other commonly used plates |

70 |

铜箔产品一览表(2) Copper Foil Products List(2)

铜箔类型

Type |

产品型号

Model |

铜箔厚度Thickness |

产品特性

Character |

产品用途

Application |

高 TG

铜箔

HTG copper foil |

HTG |

18 |

高级单面处理电解铜箔,厚度均匀、无针孔具有良好的高结合力和高温抗剥、抗拉性能。Advanced single-side treated electrolytic copper foil, uniform thickness, and pinhole- free. Strong binding force, anti- stripping and anti- stretching performance at high temperature. Effectively increased thermal stability and the conductive properties of the sheet metal |

适用于高 TG

(≥ 150 ℃ )基材Applicable to the HTG (≥ 150 ℃ ) substrates |

35 |

70 |

105 |

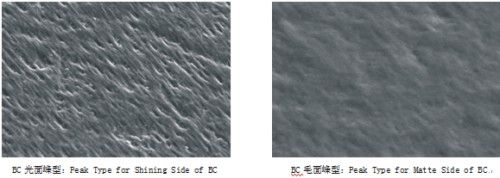

低峰值铜箔

Low peak value copper foil |

LP |

12 |

高级单面处理电解铜箔,厚度均匀、无针孔。经粗化处理,产品具有超低峰值特性,具有卓越的蚀刻性能,适用于多层 PCB 超薄内层( FR-4 ),适合精细线路或有阻抗值控制产品

Advanced single-side treated electrolytic copper foil, uniform thickness, and pinhole-free. Possessing the characteristic of ultra-low peak value by abrading the product. Outstanding performance of etching. Applicable to the ultra-thin core board (FR-4) of multi-layer PCB Suitable for fine lines or impedance control products |

适用于高频基材制作内层薄芯板

Applicable to the high-frequency base material in the production of inner thin coreboard. |

18 |

35 |

70 |

105 |

高温高延铜箔High Temperature Elongation copper foil |

HTE |

18 |

具有在高温或退火处理后的高延伸性,具有良好的黏附能力, 极高的 THE 特性,有效防止内盘裂化。 High elongation after treated with high temperature or annealing. Good adhesion ability . High THE property. Effective in the prevention of cracking plate |

适用于刚性材料及传统多层板压合要求

Applicable to the lamination of rigid materials and traditional multilayer board |

35 |

70 |

105 |

双面处理铜箔 Double-side treated copper foil |

DT |

18 |

高级双面处理铜箔,与传统 FR-4 有更好结合力 , 直接进行多层压合之特性 , 可替代化学“氧化”工序,提高 PCB 制程时效 , 卓越的蚀刻性能Advanced double-side treated copper foil, with better binding force to traditional FR-4. Direct multi-layer lamination properties. An alternative of chemical "oxidation" process, improving the aging of PCB process. Outstanding performance of etching |

用于内层芯板

For the use of inner core board |

35 |

70 |

105 |

铜箔产品一览表 (3) Copper Foil Products List(3)

铜箔类型

Type |

产品型号

Model |

可应用铜箔厚度Thickness |

产品特性

Character |

产品用途

Application |

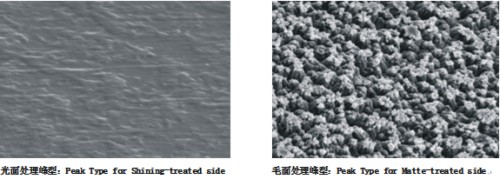

光面处理铜箔 Shining-side abrading copper foil |

RTC |

18 |

光面进行结合行高级处理 , 满足多层板在压合后有极强的固着力 , 有利于内层进行化学 “ 黑化 ” 工序与感光膜有良好的结合力。

Advanced treatment of the shining side in combining line. Strong fixing force after lamination with MLB. In favor of the inner chemical black-oxide process. Good combining strength with photographic film. |

适用于高密度,精细线路板

Applicable to high-density, fine board

|

35 |

70 |

105 |

单面光电池箔Single shining side battery copper foil |

LBEC-02 |

8 |

普通单面处理 , 具有超薄特性 , 具有较好的延展性 , 进行粘附时有良好的涂覆性。

Ordinary single-side treating. Possessing the characteristic of ultra-thin. Good ductility. Good coating when the adhesion is carried out |

用于移动电话、笔记本电脑等电子产品之锂离子电池Use for the Li-ion battery of mobile phones, notebook computers and other electronic products |

9 |

10 |

12 |

15 |

20 |

双面毛电池箔Double matte side battery copper foil |

LBEC-03 |

9 |

高级双面处理锂离子电池铜箔,具有超薄特性可双面涂覆浆料,有高承载电量的优点进行粘附时有良好的涂覆性

Advanced double-side treated copper foil in Li-ion batteries. Possessing the characteristics of ultra-thin. Slurry can be coated on both sides, and the advantage of high electric quality carrying capacity is possessed. Good coating when the adhesion is carried out |

10 |

12 |

18 |

双面光电池箔Doubie shining side battery copper foil |

LBEC-01 |

8 |

9 |

10 |

12 |

15 |

20 |

【注】以上所显示的厚度为公称厚度,敝司可根据客户需求定制8-140μm之间任意厚度铜箔。

Note:The aboved thickness is the nominal thickness, Our company can customize the thickness of copper foil bewteen 8 to 140 μm according to customer's requirements。

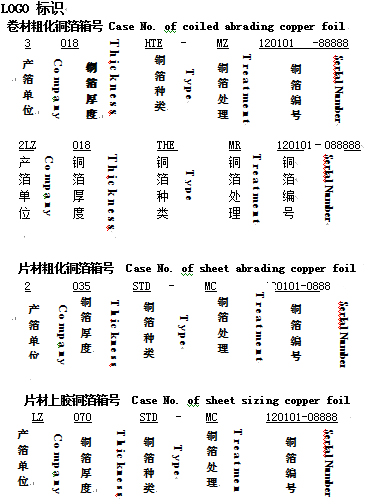

LOGO 标识

卷材粗化铜箔箱号 Case No. of coiled abrading copper foil

【说明】

⑴产箔单位-----无字母表示佛冈铜箔厂,LZ表示连州铜箔厂 Instruction:

⑴.Company-----No letters: Fogang Company LZ: Lianzhou Company

⑵铜箔厚度-----单位为μm (2). Thickness-----Unit:μm

⑶铜箔种类-----STD 表示标准铜箔 (3). Type-----STD is Standard copper foil

BC 表示电池铜箔 BC is Copper foil for battery-use

CTI 表示标准耐高电压铜箔 CTI is Standard High-voltage resistant foil

HTE 表示高温高延铜箔 HTE is High Temperature Elongation copper foil

⑷铜箔处理---

MZ 表示毛面处理镀锌铜箔 (4)Treatment---MZ is Matte-side treated zinc plating foil

MC 表示毛面处理镀铜铜箔 Matte-side treated copper plating foil

MR 表示毛面镀铜铜箔(新工艺)

MR is matte-side treated copper plating foil(the new process)

SZ 表示光面处理镀锌铜箔 Shining-side treated zinc plating foil

SC 表示光面处理镀铜铜箔 Shining-side treated copper plating foil

SR 表示光面镀铜铜箔(新工艺)

SR is shining-side treated copper plating foil(the new process)

DZ 表示双面处理镀锌铜箔 Double-side treated zinc plating foil

DC 表示双面处理镀铜铜箔 Double-side treated copper plating foil

DR 表示双面镀铜铜箔(新工艺)

DR is double-side treated copper plating foil(the new process)

DZC 表示双面处理光面镀锌毛面镀铜铜箔

Double-side treated foil with zinc plating on matte-side and copper plating on shining-side

DCZ 表示双面处理光面镀铜毛面镀锌铜箔

Double-side treated foil with copper plating on matte-side and zinc plating on shining-side

C 表示涂胶红化箔 red-adhesive foil

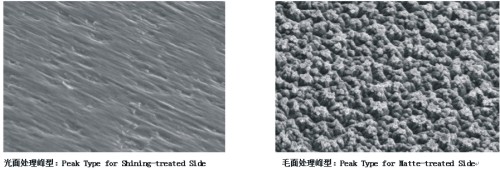

Z 表示涂胶灰化箔 gray-adhesive foil 标准粗化铜箔(STD)

技术特性

● 高级单面处理电解铜箔,厚度均匀、无针孔

● 具有良好的高结合力和高温抗剥、抗拉性能

● 有效的增大了板材的热稳定性和导电性能

● 独特的Cu-Zn合金处理改善铜箔的抗热及抗化学性

● 典型板材包括:CEM-1,CEM-3,FR-3,FR-4

Technical character

● Advanced single-side treated with electrolytic copper foil, uniform thickness, and pinhole- free.

● Strong binding force, anti- stripping and anti- stretching performance at high temperature.

● Effectively increased thermal stability and the conductive properties of the sheet metal.

● Unique Cu-Zn alloy processing to improve the heat- and chemical- resistance of copper foil

● Typical sheet metal including: CEM-1, CEM-3, FR-3, FR-4

【备注】

● 适用于双官能基及四官能基之环氧树脂基板,中层数MLB(多层板)

● 不应在高温(高于30℃)高湿(相对湿度在70%以上)条件环境下长时间贮存

● 品质依据GB/T5230-1995及IPC-4562 标准

Remarks:

● Applicable to di- and tetra-functional groups of epoxy resin laminates, middle-layers MLB

● Should not be stored at a high temperature (higher than 30 ℃) and high humidity (relative

humidity above 70%) for a long time

● The quality is based on the GB/T5230-1995 and IPC-4562 standard

General Properties 一般特性(STD 1OZ/35μ)

测试项目

Test Item |

单位

Unit |

处理条件

Condition |

测试方法Testing Method |

规范值

Specification Value |

典型值

Typical Value |

纯度 ( 包括银含量 ) |

% |

A |

IPC-TM-650 2.3.15 |

≥ 99.8 |

99.95 |

Purity ( Silver Content Included ) |

IPC-4562 3.8.1 .1 |

拉力强度 |

N/cm2 |

IPC-TM-650 2.4.18 |

≥ 28000 |

36000 |

Tensile Strength |

IPC-4562 3.5.1 |

延伸率 |

% |

IPC-TM-650 2.4.18 |

≥ 3.0 |

10.0 |

Elongation |

IPC-4562 3.5.3 |

面积重量 |

g/m2 |

IPC-TM-650 2.2.12 |

275-295 |

285 |

Area Weight |

IPC-4562 3.4.4 |

剥离强度 |

kgf/cm |

IPC-TM-650 2.4.8 |

≥ 1.60 |

2.00 |

Peeling Strength |

IPC-4562 3.5.4 |

高温抗氧化性 |

/ |

E-30/200 |

IPC-TM-650 |

S 面 不氧化 |

OK |

Heat Resistance |

M 面 不变色 |

耐化学性 |

% |

18%HCL-60

min/25℃ |

IPC-TM-650 |

≤ 4.0 |

2.5 |

Chemical resistance |

可蚀刻性 |

/ |

A |

IPC-TM-650 2.3.6 |

金属箔表面处理,应能正常的蚀刻工艺除去 |

OK |

Etchability |

IPC-4562 3.6.1 |

可焊性 |

/ |

IPC-TM-650 2.4.12 |

不应有焊料不润湿的迹象 |

OK |

Solderability |

IPC-4562 3.6.3 |

质量电阻率 |

Ω.g/m2 |

C96/35/90 |

IPC-TM-650 2.4.14 |

≤ 0.162 |

0.156 |

Surface Resistivity |

IPC-4562 3.8.12 |

粗糙度 |

光面 |

μm |

A |

IPC-TM-650 2.4.17 |

≤ 0.43 |

0.18 |

Shiningside -Ra |

IPC-4562 3.5.6 |

Roughness |

毛面 |

μm |

IPC-TM-650 2.4.17 |

≤ 10.00 |

7.00 |

Matte side-Rz |

IPC-4562 3.5.6 |

Rena rks:Typical values for reference only

【注】典型值只作参考Stand values according to IPC-4562 规格值参照IPC-4562

A=Maintain original shape,do not make handling 保持原样,不作处理

C=Temperture and humidity conditioning 在恒温恒湿的空气中处理

E=Temperature congitioning 在恒温的空气中处理

涂胶铜箔(ACC)

技术特性

● 采用酚醛树脂改性的聚乙烯醇缩醛树脂做胶粘剂

● 胶膜均匀、无杂质、无渗透孔

● 比标准涂胶箔有更好的耐浸焊和抗剥性能

● 与纸基结合具有优秀的耐热性和阻燃性

Technical character

● The phenolic resin modified polyvinyl acetal resin is used as adhesive

● Uniform film with no impurities and no penetration hole

● Better dip-soldering resistance and anti-peeling performance than the standard adhesive foil

● Excellent heat resistance and flame retardance when combinated with paper-base and flame relardant

【备注】

● 适用于高端民用电子产品及办公自动化设备的电源基板

● 不应在高温(高于30℃)高湿(相对湿度在70%以上)条件环境下长时间贮存

● 试验依据GB/T5230-1995及GB/T4722-92

Remarks:

● Applicable to the power substrate of high-end civil electronic products and

automatic office equipment

● Should not be stored at a high temperature (higher than 30 ℃) and high humidity

(relative humidity above 70%) for a long time

● All tests are based on GB/T5230-1995 and GB/T4722-92

General Properties 一般特性(ACC 1OZ/35μm)

测试项目

Test Item |

单位

Unit |

处理条件Condition |

测试方法

Testing Method |

规范值

Specification Value |

典型值

Typical Value |

纯度 ( 包括银含量 ) |

% |

A |

IPC-TM-650 2.3.15 |

≥ 99.8 |

99.95 |

Purity ( Silver Content Included ) |

IPC-4562 3.8.1 .1 |

拉力强度 |

N/cm2 |

IPC-TM-650 2.4.18 |

≥28000 |

35000 |

Tensile Strength |

IPC-4562 3.5.1 |

延伸率 |

% |

IPC-TM-650 2.4.18 |

≥4.0 |

10.0 |

Elongation |

IPC-4562 3.5.3 |

面积重量 |

g/m2 |

IPC-TM-650 2.2.12 |

275-295 |

285 |

Area Weight |

IPC-4562 3.4.4 |

剥离强度 |

kgf/cm |

IPC-TM-650 2.4.8 |

≥1.43 |

1.65 |

Peeling Strength |

IPC-4562 3.5.4 |

耐焊( 260 ℃ ) |

SEC |

S-260 |

IPC-TM-650 |

≥ 15 |

20 |

Solder Resistance |

IPC-4562 |

胶水树脂含量 |

g/m2 |

E-0.5/160 |

IPC-TM-650 |

18-22 |

18 |

Adgesive Resin Content |

胶水含挥发物比率 |

% |

E-0.5/160 |

IPC-TM-650 |

1.5-5.0 |

3.5 |

volatile Content in Adhesive |

高温抗氧化性 |

/ |

E-30/200 |

IPC-TM-650 |

S 面 不氧化 |

OK |

Heat Resistance |

M 面 不变色 |

可蚀刻性 |

/ |

A |

IPC-TM-650 2.3.6 |

金属箔表面处理,应能正常的蚀刻工艺除去 |

OK |

Etchability |

IPC-4562 3.6.1 |

可焊性 |

/ |

IPC-TM-650 2.4.12 |

不应有焊料不润湿的迹象 |

OK |

Solderability |

IPC-4562 3.6.3 |

质量电阻率 |

Ω.g/m2 |

C96/35/90 |

IPC-TM-650 2.4.14 |

≤ 0.162 |

0.158 |

Surface Resistivity |

IPC-4562 3.8.12 |

粗糙度 |

光面

Shiningside -Ra |

μm |

A |

IPC-TM-650 2.4.17 |

≤ 0.43 |

0.16 |

IPC-4562 3.5.6 |

Roughness |

毛面

Matte side-Rz |

μm |

IPC-TM-650 2.4.17 |

≤ 10.00 |

7.00 |

IPC-4562 3.5.6 |

尺寸

Size |

宽度 |

mm |

GB/T 4721-92 21 |

订单规格 ± 1.6mm |

1260 |

Width |

IPC-4562 3.4.2 |

Rena rks:Typical values for reference only

【注】典型值只作参考Stand values according to IPC-4562 规格值参照IPC-4562

A=Maintain original shape,do not make handling 保持原样,不作处理

C=Temperture and humidity conditioning 在恒温恒湿的空气中处理

E=Temperature congitioning 在恒温的空气中处理 CTI涂胶铜箔(CTI)

技术特性

● 采用酚醛树脂改性的聚乙烯醇缩醛树脂做胶粘剂

● 胶膜均匀、无杂质、无渗透孔

● 比标准涂胶箔有更好的耐浸焊和抗剥性能

● 与纸基结合具有优秀的耐热性和阻燃性

● 具有在高压(600V)无漏电起痕特性

Technical character

● The phenolic resin modified Polyvinyl alcohol acetal resin is used as adhesive

● Uniform film with no impurities and no penetration hole

● Better dip-soldering resistance and anti-peeling performance than the standard adhesive foil

● Excellent heat resistance and flame retardance when combinated with paper-base and flame relardant

● No Proof tracking under high-voltage (600V)

【备注】

● 适用于高端民用电子产品及办公自动化设备的电源基板

● 不应在高温(高于30℃)高湿(相对湿度在70%以上)条件环境下长时间贮存

● 试验依据GB/T5230-1995及GB/T4722-92

Remarks:

● Applicable to the power substrate of high-end civil electronic products and

automatic office equipment

● Should not be stored at a high temperature (higher than 30 ℃) and high humidity

(relative humidity above 70%) for a long time

● All tests are based on GB/T5230-1995 and GB/T4722-92

General Properties 一般特性(CTI 1OZ/35μm)

测试项目

Test Item |

单位

Unit |

处理条件Condition |

测试方法

Testing Method |

规范值

Specification Value |

典型值

Typical Value |

纯度 ( 包括银含量 ) |

% |

A |

IPC-TM-650 2.3.15 |

≥ 99.8 |

99.95 |

Purity ( Silver Content Included ) |

IPC-4562 3.8.1 .1 |

拉力强度 |

N/cm2 |

IPC-TM-650 2.4.18 |

≥28000 |

35000 |

Tensile Strength |

IPC-4562 3.5.1 |

延伸率 |

% |

IPC-TM-650 2.4.18 |

≥4.0 |

10.0 |

Elongation |

IPC-4562 3.5.3 |

面积重量 |

g/m2 |

IPC-TM-650 2.2.12 |

275-295 |

285 |

Area Weight |

IPC-4562 3.4.4 |

剥离强度 |

kgf/cm |

IPC-TM-650 2.4.8 |

≥1.60 |

1.80 |

Peeling Strength |

IPC-4562 3.5.4 |

耐焊 |

SEC |

S-260 |

IPC-TM-650 |

≥ 15 |

20 |

Solder Resistance |

IPC-4562 |

胶水树脂含量 |

g/m2 |

E-0.5/160 |

IPC-TM-650 |

28-40 |

31 |

Adgesive Resin Content |

胶水含挥发物比率 |

% |

E-0.5/160 |

IPC-TM-650 |

1.5-5.0 |

3.5 |

volatile Content in Adhesive |

高温抗氧化性 |

/ |

E-30/200 |

IPC-TM-650 |

S 面 不氧化 |

OK |

Heat Resistance |

M 面 不变色 |

可蚀刻性 |

/ |

A |

IPC-TM-650 2.3.6 |

金属箔表面处理,应能正常的蚀刻工艺除去 |

OK |

Etchability |

IPC-4562 3.6.1 |

CTI 值 |

V |

0.1% NH 4 Cl |

/ |

60/600 |

CTI Value |

质量电阻率 |

Ω.g/m2 |

C96/35/90 |

IPC-TM-650 2.4.14 |

≤ 0.162 |

0.158 |

Surface Resistivity |

IPC-4562 3.8.12 |

粗糙度 |

光面

Shiningside -Ra |

μm |

A |

IPC-TM-650 2.4.17 |

≤ 0.43 |

0.16 |

IPC-4562 3.5.6 |

Roughness |

毛面

Matte side-Rz |

μm |

IPC-TM-650 2.4.17 |

≤ 10.00 |

7.00 |

IPC-4562 3.5.6 |

尺寸

Size |

宽度

Width |

mm |

GB/T 4721-92 21 |

订单规格 ± 1.6mm |

1260 |

IPC-4562 3.4.2 |

Rena rks:Typical values for reference only

【注】典型值只作参考Stand values according to IPC-4562 规格值参照IPC-4562

A=Maintain original shape,do not make handling 保持原样,不作处理

C=Temperture and humidity conditioning 在恒温恒湿的空气中处理

E=Temperature congitioning 在恒温的空气中处理

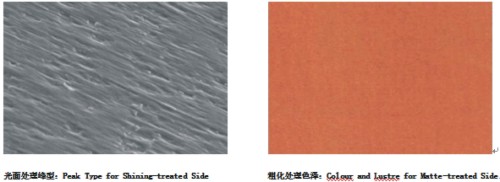

低峰值铜箔(LP)

技术特性

● 高级单面处理电解铜箔,厚度均匀、无针孔

● 经粗化处理,产品具有超低峰值特性

● 具有卓越的蚀刻性能

● 适用于多层PCB超薄内层(FR-4)

● 适合精细线路或有阻抗值控制产品

Technical character

● Advanced single-side treated electrolytic copper foil, uniform thickness, and pinhole-free

● Possessing the characteristic of ultra-low peak value by abrading the product

● Outstanding performance of etching

● Applicable to the ultra-thin layer (FR-4) of multi-layer PCB

● Suitable for fine lines or impedance control products

【备注】

● 适用于高频基材制作内层薄芯板

● 不应在高温(高于30℃)高湿(相对湿度在70%以上)条件环境下长时间贮存

● 品质依据GB/T5230-1995及IPC-4562 标准

Remarks:

● Applicable to the high-frequency material in the production of inner thin coreboard

● Should not be stored at a high temperature (higher than 30 ℃) and high humidity (relative humidity above 70%) for a long time

● The quality is based on the GB/T5230-1995 and IPC-4562 standard

General Properties 一般特性(LP 1OZ/35μm)

测试项目

Test Item |

单位

Unit |

处理条件 Condition |

测试方法

Testing Method |

规范值

Specification Value |

典型值

Typical Value |

纯度 ( 包括银含量 ) |

% |

A |

IPC-TM-650 2.3.15 |

≥ 99.8 |

99.95 |

Purity ( Silver Content Included ) |

IPC-4562 3.8.1 .1 |

拉力强度 |

N/cm2 |

IPC-TM-650 2.4.18 |

≥ 28000 |

35000 |

Tensile Strength |

IPC-4562 3.5.1 |

延伸率 |

% |

IPC-TM-650 2.4.18 |

≥ 3.0 |

10.0 |

Elongation |

IPC-4562 3.5.3 |

面积重量 |

g/m2 |

IPC-TM-650 2.2.12 |

275-295 |

285 |

Area Weight |

IPC-4562 3.4.4 |

剥离强度 |

kgf/cm |

IPC-TM-650 2.4.8 |

≥ 1.60 |

1.80 |

Peeling Strength |

IPC-4562 3.5.4 |

高温抗氧化性 |

/ |

E-30/200 |

IPC-TM-650 |

S 面 不氧化 |

OK |

Heat Resistance |

M 面 不变色 |

耐化学性 |

% |

18%HCL-60min/25 ℃ |

IPC-TM-650 |

≤ 4.0 |

2.1 |

Chemical resistance |

可蚀刻性 |

/ |

A |

IPC-TM-650 2.3.6 |

金属箔表面处理,能正常的蚀刻工艺除去 |

OK |

Etchability |

IPC-4562 3.6.1 |

可焊性 |

/ |

IPC-TM-650 2.4.12 |

不应有焊料不润湿的迹象Solder should be wetted. |

OK |

Solderability |

IPC-4562 3.6.3 |

质量电阻率 |

Ω.g/m2 |

C96/35/90 |

IPC-TM-650 2.4.14 |

≤ 0.162 |

0.153 |

Surface Resistivity |

IPC-4562 3.8.12 |

粗糙度 |

光面 |

μm |

A |

IPC-TM-650 2.4.17 |

≤ 0.43 |

0.21 |

Shiningside -Ra |

IPC-4562 3.5.6 |

Roughness |

毛面 |

μm |

IPC-TM-650 2.4.17 |

≤ 7.00 |

4.52 |

Matte side-Rz |

IPC-4562 3.5.6 |

Remarks:Typical values for reference only

【注】典型值只作参考Standard values according to IPC-4562 规格值参照IPC-4562

A=Maintain original shape,do not make handling 保持原样,不作处理

C=Temperture and humidity conditioning 在恒温恒湿的空气中处理

E=Temperature congitioning 在恒温的空气中处理

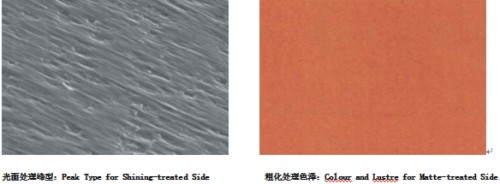

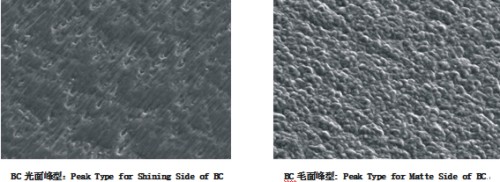

双面光电池铜箔(LBEC-01)

技术特性

● 毛面极低峰值高级锂离子电池铜箔

● 具有超薄特性

● 可根据需要单双面涂覆浆料

● 进行粘附时有良好的涂覆性

Technical character

● Copper foil in Li-ion batteries with extremely low peak value of the matte side

● Possessing the characteristics of ultra-thin

● Slurry can be coated on single side or both sides as needed

● Good coating when the adhesion is carried out

【备注】

● 用于移动电话、笔记本电脑等电子产品之锂离子电池

● 不应在高温(高于30℃)高湿(相对湿度在70%以上)条件环境下长时间贮存

● 品质依据GB/T5230-1995、SJ/T11483-2014及IEC 标准

Remarks:

● Applicable to the Li-ion battery of mobile phones, notebook computers and other electronic products

● Should not be at a high temperature (higher than 30 ℃) and high humidity (relative humidity above 70%) for a long time storage

● The quality is based on the GB/T5230-1995、SJ/T11483-2014 and IEC standard

General Properties 一般特性(LBEC-01/8μm)

测试项目

Test Item |

单位 Unit |

处理条件 Condition |

测试方法

Testing Method |

规范值 Specification Value |

典型值 Typical Value |

纯度 ( 包括银含量 ) |

% |

A |

IPC-TM-650 2.3.15 |

≥ 99.8 |

99.95 |

Purity(Silver Content Included) |

SJ/T11483-2014 |

拉力强度 |

N/cm2 |

IPC-TM-650 2.4.18 |

≥ 29400 |

33000 |

Tensile Strength |

SJ/T11483-2014 |

延伸率 |

% |

IPC-TM-650 2.4.18 |

≥ 3.0 |

7.0 |

Elongation |

SJ/T11483-2014 |

面积重量 |

g/m2 |

IPC-TM-650 2.2.12 |

70-75 |

73 |

Area Weight |

SJ/T11483-2014 |

高温抗氧化性 |

/ |

E-15min/140℃ |

IPC-TM-650 |

S 面 不氧化 |

OK |

Heat Resistance |

M 面 不变色 |

表面润湿张力 |

10-3N/m |

A |

GB/T 22638.4 |

≥ 32 |

50 |

Surface wetting tension |

SJ/T11483-2014 |

粗糙度 |

光面 |

Ra |

μm |

A |

IPC-TM-650 2.4.17 |

≤ 0.3 |

0.22 |

Shiningside |

SJ/T11483-2014 |

Roughness |

毛面 |

Rz |

≤ 3.0 |

1.5 |

Matte side |

SJ/T11483-2014 |

Remarks:Typical values for reference only

【注】典型值只作参考Standard values according to IPC-4562 规格值参照IPC-4562

A=Maintain original shape,do not make handling 保持原样,不作处理

C=Temperture and humidity conditioning 在恒温恒湿的空气中处理

E=Temperature congitioning 在恒温的空气中处理

单面光电池铜箔(LBEC-02)

技术特性

● 普通单面处理

● 具有超薄特性

● 具有较好的延展性

● 进行粘附时有良好的涂覆性

Technical character

● Ordinary single-side treating

● Possessing the characteristic of ultra-thin

● Good scalability

● Good coating when the adhesion is carried out

【备注】

● 用于移动电话、笔记本电脑等电子产品之锂离子电池

● 不应在高温(高于30℃)高湿(相对湿度在70%以上)条件环境下长时间贮存

● 品质依据GB/T5230-1995、SJ/T11483-2014及IEC 标准

Remarks:

● Use for the Li-ion battery of mobile phones, notebook computers and other electronic products

● The foil should not be at a high temperature (higher than 30 ℃) and high humidity (relative humidity above 70%) for a long time storage

● the quality is based on the GB/T5230-1995、SJ/T11483-2014 and IEC standard

General Properties 一般特性(LBEC-02/9μm)

测试项目

Test Item |

单位

Unit |

处理条件

Condition |

测试方法

Testing Method |

规范值 Specification Value |

典型值

Typical Value |

纯度 ( 包括银含量 ) |

% |

A |

IPC-TM-650 2.3.15 |

≥ 99.8 |

99.95 |

Purity ( Silver Content Included ) |

SJ/T11483-2014 |

拉力强度 |

N/cm2 |

IPC-TM-650 2.4.18 |

≥ 30000 |

35000 |

Tensile Strength |

SJ/T11483-2014 |

延伸率 |

% |

IPC-TM-650

2.4.18 |

≥ 2.5 |

5.8 |

Elongation |

SJ/T11483-2014 |

面积重量 |

g/m2 |

IPC-TM-650 2.2.12 |

85-90 |

88 |

Area Weight |

SJ/T11483-2014 |

高温抗氧化性 |

/ |

E-15min/140℃ |

IPC-TM-650 |

S 面 不氧化 |

OK |

Heat Resistance |

M 面 不变色 |

表面润湿张力 |

10-3N/m |

A |

GB/T 22638.4 |

≥ 32 |

50 |

Surface wetting tension |

SJ/T11483-2014 |

粗糙度 |

光面 |

μm |

A |

IPC-TM-650 2.4.17 |

≤ 0.40 |

0.22 |

Shiningside -Ra |

SJ/T11483-2014 |

Roughness |

毛面 |

μm |

IPC-TM-650 2.4.17 |

≤ 4.0 |

2.3 |

Matte side-Rz |

SJ/T11483-2014 |

Remarks: Typical values for reference only

【注】典型值只作参考Standard values according to IPC-4562 规格值参照IPC-4562

A=Maintain original shape,do not make handling 保持原样,不作处理

C=Temperture and humidity conditioning 在恒温恒湿的空气中处理

E=Temperature congitioning 在恒温的空气中处理 |

| |

|