【H2135 CEM-3】

特性/ Features

优秀的机械加工性,可冲孔加工,钻孔加工钻头使用寿命可延长

Excellent mechanical processability, punching process applicable, longer drill bit life .

电性能与FR-4相当,加工工艺与FR-4相同

Electrical properties and PCB processing similar to FR-4.

可依需求提供高CTI的CEM-3板材/ High CTI CEM-3 available upon request (CTI 600);

应用领域/ Applications

汽车电子、仪器仪表、信息家电、自动控制器、游戏机等。

Automotive electronics,apparatus and instrument,information household appliances,remote control unit,game machine,and etc.

主要特性 / General properties

检测项目

Item |

单位

Unit |

检测条件

Test Condition |

规范值

Spec |

典型值

Typical Value |

玻璃化转变温度 Tg |

℃ |

DSC |

≥120 |

128.5 |

剥离强度 1oz Peel Strength |

N/mm |

260 ℃ , 10S |

≥1.05 |

1.54 |

热应力 Thermal stress |

S |

260 ℃ ,solder dip |

> 10 |

60s |

弯曲强度 Flexural Strength |

N/mm2 |

经向 LW |

≥276 |

380 |

纬向 CW |

≥186 |

280 |

燃烧性 Flammability |

- |

E 24/125 |

UL94V-0 |

V-0 |

表面电阻 Surface Resistivity |

MΩ |

After moisture |

≥1.0×104 |

2.37×106 |

体积电阻 VolumeResistivity |

MΩ·cm |

After moisture |

≥1.0×106 |

2.67×108 |

介电常数 Dielectric Constant |

- |

1 MHZ C 24/23/50 |

≤5.4 |

4.7 |

介质损耗角正切 Loss Tangent |

- |

1 MHZ C 24/23/50 |

≤0.035 |

0.016 |

耐电弧 Arc Resistance |

S |

D48/50 + D0.5/23 |

≥60 |

120 |

击穿电压 Dielectric Breakdown |

KV |

D48/50 + D0.5/23 |

≥40 |

55 |

吸水率 Moisture Absorption |

% |

D24/23 |

≤0.5 |

0.17 |

热分解温度 Td |

℃ |

Weight Loss 5% |

- |

310 |

CTE Z-axis |

Alpha 1 |

ppm / ℃ |

TMA |

- |

63 |

Alpha 2 |

ppm / ℃ |

- |

350 |

50 - 260 ℃ |

% |

- |

4.5 |

T288 |

min |

TMA |

- |

1 |

相比漏电起痕指数 CTI |

V |

IEC-60112 |

175 ~ 250 |

200 |

Specimen Thickness : 1.6mm ;

Explanation: C: Humidity conditioning; D: Immersion conditioning in distilled water ;

E: Temperature conditioning ;

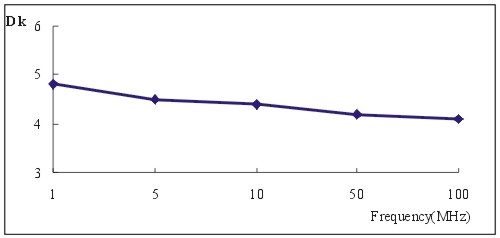

◆ 介电常数 / Dielectric constant

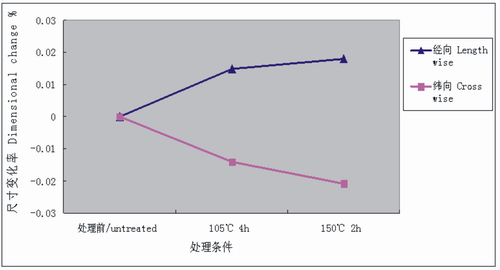

◆ 热处理后板材经纬向尺寸变化

Dimensional change in cross and length direction after heat treatment

产品系列 / Purchasing information

厚度 Thickness |

铜箔 Copper foil |

标准尺寸 Standard size |

0.6~ 3.2mm |

18um ~ 105um |

37"×49" 、 41"×49" 、 43"×49" |

※ Other sheet size and thickness could be available upon request

【H2135hf 无卤CEM-3 Halogen-free】

特性/ Features

优秀的机械加工性,可冲孔加工,钻孔加工钻头使用寿命可延长

Excellent mechanical processability, punching process applicable, longer drill bit life .

电性能与FR-4相当,加工工艺与FR-4相同

Electrical properties and PCB processing similar to FR-4.

可依需求提供高CTI的无卤CEM-3板材/ High CTI Halogen-free CEM-3 available upon request (CTI 600);

可依需求提供Tg≥140的无卤CEM-3板材/TG≥140 Halogen-free CEM-3 available upon request.

应用领域/ Applications

汽车电子、仪器仪表、信息家电、自动控制器、游戏机等。

Automotive electronics,apparatus and instrument,information household appliances,remote control unit,

game machine,and etc.

主要特性 / General properties

检测项目

Item |

单位

Unit |

检测条件

Test Condition |

规范值

Spec |

典型值

Typical Value |

玻璃化转变温度 Tg |

℃ |

DSC |

≥120 |

128.5 |

剥离强度 1oz Peel Strength |

N/mm |

260 ℃ , 10S |

≥1.05 |

1.54 |

热应力 Thermal stress |

S |

260 ℃ ,solder dip |

> 10 |

60s |

弯曲强度 Flexural Strength |

N/mm2 |

经向 LW |

≥276 |

380 |

纬向 CW |

≥186 |

300 |

燃烧性 Flammability |

- |

E 24/125 |

UL94V-0 |

V-0 |

表面电阻

Surface Resistivity |

MΩ |

After moisture |

≥1.0×104 |

2.37×106 |

体积电阻 VolumeResistivity |

MΩ·cm |

After moisture |

≥1.0×106 |

2.67×108 |

介电常数 Dielectric Constant |

- |

1 MHZ C 24/23/50

|

≤5.4 |

4.7 |

介质损耗角正切 Loss Tangent |

- |

1 MHZ C 24/23/50

|

≤0.035 |

0.016 |

耐电弧 Arc Resistance |

S |

D48/50 + D0.5/23 |

≥60 |

120 |

击穿电压 Dielectric Breakdown |

KV |

D48/50 + D0.5/23 |

≥40 |

55 |

吸水率 Moisture Absorption |

% |

D24/23 |

≤0.5 |

0.17 |

热分解温度 Td |

℃ |

Weight Loss 5% |

- |

335 |

卤素含量Halogen content |

Cl |

ppm |

EDX-GP |

≤900 |

310 |

Br |

ppm |

≤900 |

30 |

Cl+Br |

ppm |

≤1500 |

350 |

T288 |

min |

TMA |

- |

1 |

相比漏电起痕指数 CTI |

V |

IEC-60112 |

175 ~ 250 |

200 |

Specimen Thickness : 1.6mm ;

Explanation: C: Humidity conditioning; D: Immersion conditioning in distilled water ;

E: Temperature conditioning ;

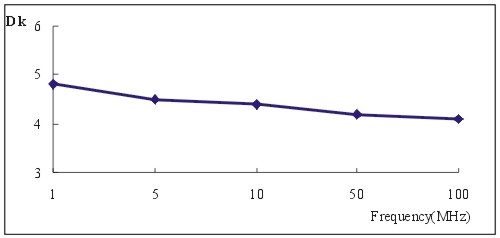

◆ 介电常数 / Dielectric constant

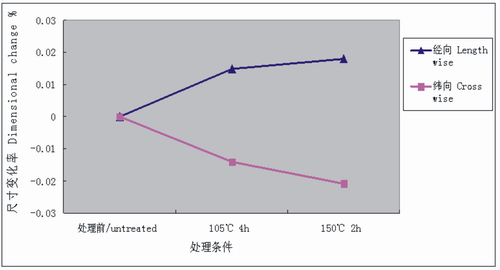

◆ 热处理后板材经纬向尺寸变化

Dimensional change in cross and length direction after heat treatment

产品系列 / Purchasing information

厚度 Thickness |

铜箔 Copper foil |

标准尺寸 Standard size |

0.6~ 3.2mm |

18um ~ 105um |

37"×49" 、 41"×49" 、 43"×49" |

※ Other sheet size and thickness could be available upon request

【高性能散热材料——Thermal conductivity CEM-3 (HA30)】

特性/ Features

良好的导热性能,热导率≥1.0W/ m?K

Excellent thermal conductivity, ≥1.0W/ m?K

优异的耐热性能,适应无铅制程

Excellent solder heat endurance, Lead-free compatible CEM-3 laminate

基材白色,不透明,遮光性好

White and opaque with good color-change resistance

优秀的机械加工性

Excellent mechanical processability

应用领域/ Applications

LED背光源、家用照明、汽车电子、电源电路等(见下图)

LED backlight module、consumer Lighting、Automotive electronics、Power supplies(refer to figure)

主要特性 / General properties

检测项目

Item

|

单位

Unit

|

检测条件

Test Condition

|

规范值

Spec

|

类型 1

Type 1

|

类型 2

Type 2

|

热导率Thermal Conductivity

|

W/ m·K |

ASTM D 5470 |

≥1.0 |

1.02 |

1.51 |

玻璃化转变温度 Tg |

℃ |

DSC |

≥110 |

120 |

120 |

剥离强度1oz Peel Strength

|

N/mm |

288 ℃ , 10S |

≥1.05 |

1.56 |

1.53 |

热应力Thermal stress

|

S |

288 ℃ ,solder dip |

> 10 |

60s No delamination |

60s No delamination |

弯曲强度 Flexural Strength |

N/mm2 |

经向 LW |

≥276 |

326 |

326 |

纬向 CW |

≥186 |

235 |

235 |

燃烧性 Flammability |

- |

E 24/125 |

UL94V-0 |

V-0 |

V-0 |

表面电阻Surface Resistivity

|

MΩ |

After moisture |

≥1.0×104 |

4.62×106 |

4.62×106 |

体积电阻VolumeResistivity

|

MΩ·cm |

After moisture |

≥1.0×106 |

3.76×108 |

3.76×108 |

介电常数Dielectric Constant

|

- |

1 MHZ C 24/23/50

|

—— |

5.1 |

5.6 |

介质损耗角正切Loss Tangent

|

- |

1 MHZ C 24/23/50

|

≤0.035 |

0.019 |

0.019 |

耐电弧 Arc Resistance |

S |

D48/50 + D0.5/23 |

≥60 |

128 |

128 |

击穿电压Breakdown Voltage

|

KV |

IPC-TM-650 2.5.6 .2

D48/50 + D0.5/23

|

≥40 |

60 |

60 |

吸水率Moisture Absorption

|

% |

D24/23 |

≤0.5 |

0.35 |

0.35 |

CTI |

V |

IEC-60112 |

≥600 |

600 |

600 |

Specimen Thickness : 1.0mm ;

Explanation:

C: Humidity conditioning;D:Immersion conditioning in distilled water ; E:Temperature conditioning ;

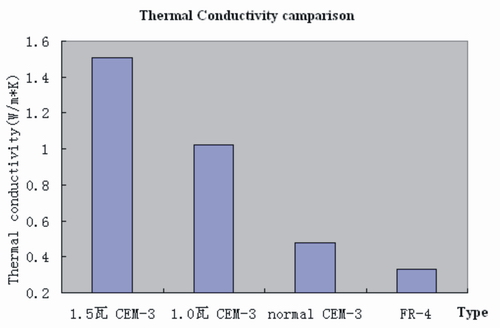

导热CEM-3和其他材料热导率比较 Thermal Conductivity camparison

主要应用Applications

产品系列 / Purchasing information

厚度 Thickness |

铜箔 Copper foil |

标准尺寸 Standard size |

0.8~ 3.2mm |

18um ~ 105um |

37"×49" 、 41"×49" 、 43"×49" |

※ any specific inquuiry could be available upon request

【覆铜板厚度公差表】

CCL thickness and tolerance list

标准厚度 mm

standard thickness

|

厚度公差 mm / tolerance |

Class B/L 级 |

Class C/M 级 |

0.025 ~ 0.119 |

±0.018 |

±0.013 |

0.120 ~ 0.164 |

±0.025 |

±0.018 |

0.165 ~ 0.299 |

±0.038 |

±0.025 |

0.300 ~ 0.499 |

±0.050 |

±0.038 |

0.500 ~ 0.785 |

±0.064 |

±0.050 |

0.786 ~ 1.039 |

±0.100 |

±0.075 |

1.040 ~ 1.674 |

±0.130 |

±0.075 |

1.675 ~ 2.564 |

±0.180 |

±0.100 |

2.565 ~ 3.579 |

±0.230 |

±0.130 |

3.580 ~ 6.350 |

±0.300 |

±0.150 |

※ 一般情况下,华正电子依照二级厚度公差(B/L级)要求接单作业,加严厚度公差(三级公差C/M级)或特殊厚度公差要求可协商解决。

Commonly , we will accept the order form according to the Class B/L , the Class C/M or other special tolerance could be available upon request.

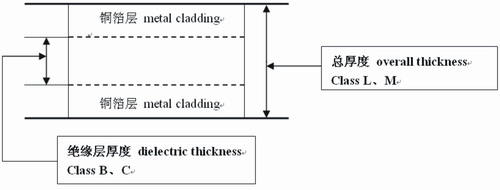

※ Class B、C表示不含铜箔的板材厚度; Class L、M为含铜箔在内的板材厚度;

Class B、C figure the dielectric thickness ;Class L、M figure the overall thickness;

如下图 / As follows:

|