【高性能散热材料——铝基覆铜板】

Al-Substrate CCL

产品简介/ Product description

华正新材铝基板具有高导热性、高耐热性、良好的电绝缘性和极佳的环境可靠性的特点,其导热系数为传统覆铜板的4 ~15倍。采用该基板制作的PCB能将电子元件产生的热量经由基板结构,快速传导至后端散热基座或其他散热模组。其结构由铜箔电路层、导热绝缘层以及金属基板所组成,导热层是由特殊的高分子树脂和导热填充料制作而成,相关产品已通过多项苛刻的长时间环境测试,获得国际认证。

华正新材拥有强大的研发实力,相续开发出多款高性能铝基板产品。热导率为1.0~5.0 W/ m?K,可满足中高端产品需求,性价比高。所有产品均通过RoHS等国际规范的禁用物质检验,兼顾良好的产品特性与低碳环保之趋势。

Thermal conduct Al-Substrate CCL provides the advantages of high thermal conductivity, Excellent solder heat endurance, Excellent Breakdowm Voltage, reliability, Thermal Conductivity is about four~ fifteen times higher than the FR-4 , PCB produced by the substrate can transfer heat , which is electrionic components generate , throughing the substrate structure rapid conduct to the back-end cooling base or other cooling modules.

Al-Substrate CCL is a sandwich structure, which includes layers of conductor ,insulator and metal base. In genaral, this insulator is made of epoxy resin and high thermal Conductivity filler. The products have been through a number of demanding for a long time environmental testing, access to international certification.

Huazheng new material has a strong R&D strength, which continued to develop avariety of high Thermal Conductivity products. Thermal conductivity 1.0~5.0 W/ m?K,It can fit the demand of high end and mid-range products,with high cost performance. All products pass RoHS standard, have good property andmeet low-carbon environmental trend.

特性/ Features

优异的散热性能 Excellent thermal conductivity

电气绝缘性能佳 Excellent Breakdowm Voltage

符合RoHS要求 RoHS compliance

良好的耐热性能 Excellent solder heat endurance

良好的机械加工性能 Excellent mechanical properties

电磁屏蔽性能 Excellent electromagnetic shielding

可直接外接散热装置 Can use external cooling device directly

优良的性价比 High cost performance

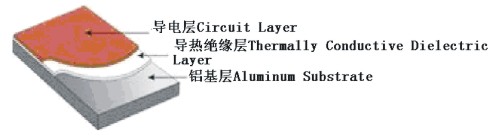

基本结构/ Basic Structure

典型结构

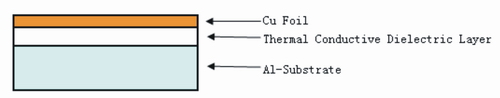

单面铝基板single Al-Substrate CCL

单面铝基板产品能够针对各种铜厚、绝缘层特性、金属板规格需求,提供符合客户要求的高性能产品;

Single Al-Substrate CCL offers various kinds ouf combination of base metal,copper foil,and dielectric layers to meet the general requirement of single layer thermal conductive printed circuit board

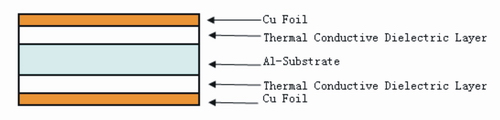

双面铝基板Double Al-Substrate CCL

双面铝基板产品其为导热绝缘层双面黏贴铜箔的结构,适用于一般用途多层板。

Double Al-Substrate CCL is good for general requirement ouf multilayer or thineer shape printed circuit board. ACCL is a sandwich structure, which includes layers of copper foil, thermal conductive dielectric layer.l

说明 / Instruction

导电层—电解铜箔 / Circuit Layer – Electrolysis copper foil

导热绝缘层—以最小的热阻提供电学上的绝缘,分为玻璃布增强型和无玻璃布增强型两种

Thermally Conductive Dielectric Layer –This offers electrical isolation with minimum thermal resistance. two types: Fiberglass support & non-fiberglass support.

铝基层—是整个结构的支撑和热量的发散,材料为铝合金板

Aluminum SubstrateIt –supports the entire structure and conducts the heat. The material is aluminum alloy plate.

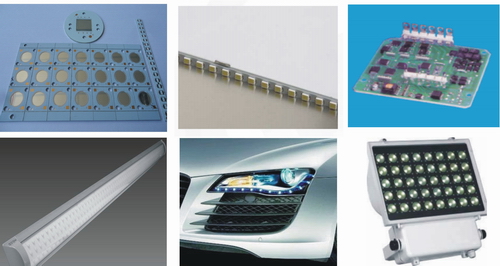

应用领域 / Application

照明、LED显示 LED lighting、Public lighting、Backlight module、outdoor LED display

汽车应用 Automotive (Vehiche lighting、regulator、converters、Power module)

工业电子 Industrial electronics(DC-DC converter、Power supplies、Solid-State Relays transistor modules)

通讯产品 Digital、PC、Audio

需要高散热的领域 The area needs high heat dissipation

产品分类 /Type

Type1:普通型,一般应用在家用照明、户外显示屏、背光源领域

General purpose. It is used widely in consumer lighting、outdoor LED display and backlight applications

Type2:标准导热型,广泛应用在公用照明、通讯数码、汽车应用领域

Standard thermal conductivity. It is used in public lighting、Digital、PC、Audio、Automotive applications

Type3:高导热型,应用在大功率、亮度LED、汽车应用、工业电子领域

High thermal conductivity. It is used in high power LED lighting、Automotive applications、Industrial electronics

Type4:高导热低热阻型,可使用需要高导热及高功率方面

High thermal conductivity、Low thermal resistance. It is used in high power applications

Type5:高韧性型,具有良好的折弯性能,应用在非平面空间领域;

High toughness. It is used in the field of no-plat, with good bending properties.

主要性能 Main property 表Table1

项目 Item |

处理条件

Test condition |

单位 Units |

指标值

Spec |

典型值 Typical Value |

类型 1 |

类型 2 |

类 型 3 |

类型 4 |

类型 5 |

Type1 |

Type2 |

Type3 |

Type4 |

Type5 |

1.0 瓦 |

1.5 瓦 |

2.0 瓦 |

3.0 瓦 |

2.0 瓦 |

热阻 * Note 1

thermal resistance |

ASTM E-1461 |

K·cm2/W |

< 1.0 |

0.77 |

|

|

|

|

< 0.7 |

|

0.61 |

|

|

|

< 0.5 |

|

|

0.41 |

|

0.41 |

< 0.4 |

|

|

|

0.33 |

|

热导率 * Note 1 ThermalConductivity |

ASTM E-1461 |

W/m·K |

≥1.0 |

1.1 |

|

|

|

|

≥1.5 |

|

1.6 |

|

|

|

≥2.0 |

|

|

2.2 |

|

2.2 |

≥3.0 |

|

|

|

3.0 |

|

剥离强度 1OZ

Peel Strength |

热应力前 |

N/mm |

≥1.2 |

1.82 |

1.83 |

1.80 |

1.75 |

1.80 |

热应力后 |

1.75 |

1.73 |

1.76 |

1.70 |

1.76 |

热应力

Thermal Stress |

288 ℃ ,solder dip |

S |

≥120 |

180S No delamination |

300*10s/cycle solder dip |

cycle |

≥6 次 |

6 次 No delamination |

表面电阻 Surface Resistivity |

C96/35/90 |

MΩ |

≥104 |

106 |

106 |

106 |

106 |

106 |

E-24/125 |

≥10 3 |

105 |

105 |

105 |

105 |

105 |

体积电阻 Volume Resistivity |

C96/35/90 |

MΩ·cm |

≥106 |

107 |

107 |

107 |

107 |

107 |

E-24/125 |

≥103 |

105 |

105 |

105 |

105 |

105 |

击穿电压( AC )

* Note 2 空气环境Dielectric Breakdown |

IPC-TM-650 2.5.6 .2 |

KV |

≥3 |

100μm |

4.3 |

4.3 |

4.3 |

4.3 |

4.3 |

≥4 |

125μm |

5.0 |

5.0 |

5.0 |

— |

— |

≥5 |

150μm |

6.0 |

6.0 |

6.0 |

— |

— |

介电常数( 1MHz ) Dielectric Constant |

C 24/23/50 |

— |

— |

5.1 |

5.3 |

5.5 |

5.8 |

5.5 |

IPC-TM-650 2.5.5 .2 |

耐电弧

Arc Resistance |

D48/50 + D0.5/23 |

S |

≥60 |

120 |

120 |

120 |

120 |

120 |

IPC-TM-650 2.5.1 |

燃烧性 Flammability |

E-24/125 |

— |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

玻璃化温度 Tg |

DSC |

℃ |

≥110 |

121.2 |

122.6 |

121.8 |

122.3 |

121.8 |

热分解温度 Td |

TGA ( Wt5%loss ) |

℃ |

≥360 |

400 |

400 |

400 |

400 |

400 |

吸水率

Water Absorption |

D-24/23 |

% |

≤1.5 |

0.51 |

0.43 |

0.56 |

0.49 |

0.56 |

IPC-TM-650 2.6.2 .1 |

CTI |

IEC60112 |

V |

≥600 |

600 |

600 |

600 |

600 |

600 |

上述测试数据为典型值而非保证值。

*备注1:热阻试样采用铝合金板厚度1.0mm、铜箔厚度35um、绝缘层厚度75um的铝基板试样测试并计算所得(引用标准:CPCA4105-2010《印制电路用金属基覆铜箔层压板》行业标准)。

*Note1:Thermal resistance samples use Aluminum SubstrateIt with 1mm aluminium alloy plate,35um copper foil and 75um Dielectric layer, Using ASTM E-1461 test method and calculate the result(According to CPCA4105-2010《 Printed Circuit Metal Base Copper-Clad Laminate 》).

*备注2:绝缘层耐电压测试值采用铝基覆铜板测试所得,而非制作成PCB的测试值。由于客户线路设计及空气导电等因素,MPCB的测试值会低于基板的值。

*Note2:Dielectric Breakdown Voltage test value refers to the value of Al-Substrate CCL,and not Al-Substrate PCB test value. Because of design and the air facor, the Al-Substrate PCB test value will be lower than the value of substrate.

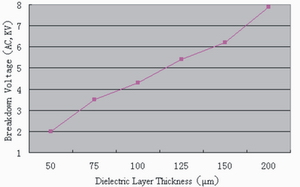

绝缘层厚度与耐电压关系Relationship of Dielectric Layer Thickness and Breakdown Voltage

产品规格Specification

标准尺寸 Standard Size |

500×610mm 、 550×610mm 、 500×1220mm 、 550×1220mm

1000×1220mm 、 1100×1220mm |

导电层 Circuit Layer(电解铜箔 Copper foil) |

18μm、35μm、70μm、105μm(Hoz、1oz、2oz、3oz) |

导热绝缘层厚度Dielectric Layer Thickness |

100μm、125μm、150μm(1.0~2.0 瓦)100μm(non-fiberglass support) |

铝基板厚度 Thickness |

0.6mm 、 0.8mm 、 1.0mm 、 1.2mm 、 1.5mm 、 1.6mm 、 2.0mm 、 3.0mm (厚度≤ 1.0 或 3oz 铜箔建议铝型选用 5052 ) |

铝板类型及处理方法 Aluminum Substrate Type |

1100 、 1060 、 5052 、 6061 阳极氧化法 Anodization |

保护膜类型 Masking Film |

PET 、 PI |

如有特殊要求,可定制any specific inquuiry could be available upon request。

可靠性测试数据/ ReliabilityTesting Data

测试基板:HA50-type3(铝板厚度:1.4mm,绝缘层厚度:100μm,铜箔厚度:1oz)

Tested substrate: HA50-type3 (Aluminum thichness: 1.4mm, thermal conductive dielectric layer thinckness: 100μm, copper foil thinckness: 1oz)

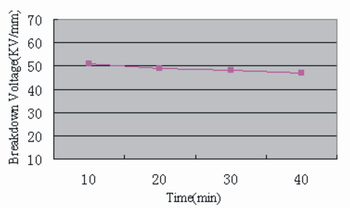

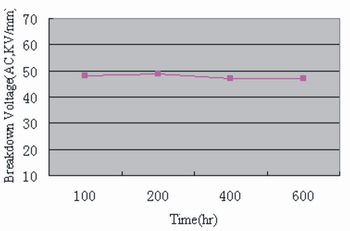

(1) 绝缘层耐电压测试 Dielectric Breakdown Voltage

HA50产品在经过漂锡后以及长期环境冷热冲击后仍然可保持良好的耐电压特性。

HA50 product has excellent dielectric Breakdown Voltage even after solder dippling

|

|

图1.漂锡测试260℃

Figure 1. Breakdown Voltage after aging test at 260℃ |

图2.冷热环境测试-40℃/30min至150℃/30min

Figure 2. Breakdown Voltage after aging test at -40℃/30min&150℃/30min |

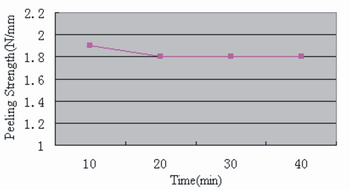

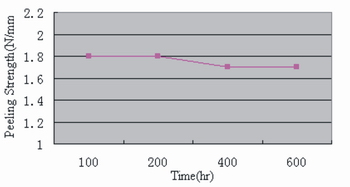

(2) 剥离强度测试 Peeling Strength

HA50产品在经过漂锡后以及长期环境冷热冲击后仍然可保持良好的剥离强度。

HA50 product has excellent Peeling Strength even after solder dippling

|

|

图3.漂锡测试260℃

Figure 1. Breakdown Voltage after aging test at 260℃ |

图4.冷热环境测试-40℃/30min至150℃/30min

Figure 2. Breakdown Voltage after aging test at -40℃/30min&150℃/30min |

| |

|

|